Forum Replies Created

-

AuthorPosts

-

HostgatorMember

Indeed, I was talking about the engine’s anti-knock sensor when I mentioned it — I was also thinking about different sensors that might also handle knocking, as well. It is the device that advances or retards the timing automatically as it senses the stresses on the engine. And, yes, it is the same report you get at AutoZone or another shop, though, their tests are nowhere near as detailed as the reports you will get from the dealer, for obvious reasons (they have the latest full diagnostic software from the factory that independents can’t usually get).

The transmission fluid filter is an internal filter that keeps debris and metal shards from running around the tranny, possibly harming delicate, small parts and openings. It is usually located on the output side of the transmission fluid pan so that the nasty stuff will stay in the sump where it belongs.

Need a replacement transmission? Quality transmissions are hard to find. Free estimate to your email.HostgatorMemberThis is a good news, bad news item. The good news is that one solenoid is usually accessible on the transmission’s valve body. The bad news is that the second on used is on the inside of the valve body. And, yes, getting to the solenoids means that you do have do some partial disassembly to get to the valve body and get the cover off.

Indeed, unless you are skilled at mechanical takedowns, then I would suggest taking the Sportage to an independent shop where a technician can handle the work.

Now, it is possible that you might get lucky and find that the solenoid on the outside of the valve body is the one you need. The reason being is that the solenoids are used together to determine the actual gear setting. For example, it is possible that the solenoid controlling first and third might be on the outside of the valve body while second and fourth may be on the inside of the valve body, but you can’t be sure of that. So, you will have to assume that if the problem is in the solenoids that you will have to do a minimal teardown to reach them.

I would recommend, though, that as I noted, the teardown work be left to a knowledgeable technician as they will make sure it is done quickly and properly unless you feel confident that you can do that work and that you have the tools, as well.

HostgatorMemberBefore you head out to the local junkyard looking for a compatible transmission, I would either performance and OBD diagnostic. The reason for my recommendation is that I don’t believe you have a transmission problem. It sounds to me as if it could be a sensor that has failed or is failing. I would start with the anti-knock filter since you say the transmission is knocking, it would seem to me to be best bet.

You can tell that this is a mechanical problem rather than a transmission issue because it is located in a specific gear, rather than affecting the tranny as a whole. Indeed, that is one of the strongest telltales that the issue is mechanical. If it were a transmission problem or a problem within the transmission (honestly two different ideas, for example, if it is a transmission problem, the tranny then it would be failing in more than one gear. Further, the transmission would likely be exhibiting problems such as slipping in all gears; there might be problems with transmission electronics such as the MAP sensor failing to do its job, turning your pickup’s performance into poor capability, and more.) If it is a problem within the transmission then it would be exhibiting other problems. For example, if it were a problem with the input shaft then you would likely have a pickup with very loud noises coming from that area as the input shaft complained that it had a problem very pointedly.

Believe me when I tell you it’s to your advantage if you take your pickup into a local full-service transmission shop with NIASE-certified technicians. They will quickly isolate the problem from which your pickup is suffering and report out on it. I would be willing to bet you a large cup of iced coffee you will find that the OBD report shows lots of 07XX errors which, by the way, are for various systems within the transmission. Let me know what happens, please.

HostgatorMemberIf it’s happening when your F-150 is in two-wheel-drive then I would have the gear selector looked at for starters. It sounds as if it may be slightly out-of-kilter and instead of clearing the 4WD selection (your F-150 is “drive-by-wire” or computer-controlled when it comes to choosing the gearing), your pickup is still in 4WD.

I’d bring it into a good repair facility of a dealership to have it checked out ASAP because of your upcoming move.

It is possible that there is more to the problem than just the selector as it could be in anywhere in the electronics, however, I think if you have a diagnostic run, you will find the return will put the problem somewhere in the front-end of the electronics.

The good news is that the problem is, I think, where it is in the front end of the electronics chain. This means it should be relatively easy to access and fix. The bad news is that it could be in the console area where something is either shorting or open and giving a false indication to the engine control module. If that is the case and the console has to be opened then it could mean you could be without your ride for the day. However, when it’s fixed you should be able to go on your way in two-wheel or four-wheel.

HostgatorMemberFirst a question: do you have self-locking hubs or do you have to backup and turn the hubs to put it into four-wheel-drive? If you do, then you may have a problem because you may have switched into four-wheel-drive without ensuring the differential and gears were in sync. You can’t know that until you get into the differential and look at things.

If on the other hand, you have an all-electronic transmission, four-wheel-drive setup then I suspect everything is fine.

I have found that when I have driven Ford 4X4s in the past that if you leave your vehicle in four-wheel-drive and attempt to turn the steering wheel beyond 80 degrees or so, the transmission starts to complain a lot with grinding and such.

So, here’s what I would suggest: put the truck into two-wheel-drive and leave it there and then make sure your trailer is hooked up correctly. I don’t think there’s anything wrong with the transmission, I suspect it is the four-wheel-drive that you are hearing complain and if you don’t need it, then there should be nothing wrong with you hauling a trailer to your new home.four-wheel-drive

HostgatorMemberTo add a bit: Your problem still is in the return lines, but, I would also re-check the flywheel installation. If it isn’t mating to the clutch plate correctly, then you will have problems once you have cleared the return line problem. Hope this helps. MS.

HostgatorMemberAfter reading your question, what you are describing is a blockage in one of the transmission return lines. The return lines route the transmission fluid through the transmission intercooler before it begins its trip back through the tranny.

Since there’s only one line open, flow through the transmission has been cut by more than 50 percent as there are probably buildups within the transmission that take any flow and cut it further. So, since the flow is weak already and lack of the secondary return line is keeping the transmission from working at all.

That’s why you are not having any sort of PRNDL action when you go through the gears.

To fix this, you will have to unhook the slack hose and look at it closely. Is there a buildup in the connector? Has the connector been pinched or damaged by being dropped on the ground or, perhaps, crushed underneath a boot accidentally as you worked on the transmission? If the connector seems okay and clear, I would take a piece of hard-drawn copper wire — you can find it in some old TV cable — cut a length and then snake it down the connector to see if there might now be a buildup of deposits at or near the hose endpoint. Sometimes, a slight buildup near the end of a hose encourages further buildup and can pinch things off until there’s no flow.

If everything on the hose side looks good, take a close look at the connector into which the hose slips. It is possible that when you pulled the hose piece out of the connector that something might have distorted or pinched off in the connector itself. If this is the case, you will have to replace the connector so your transmission has fluid flow again. Without strong fluid flow, even though the transmission has been repaired and placed back in the housing, there will be no flow and no gearing as well.

Check the connections and I think you will find buildups or damage on either side. If this is the case, then you will have to swap out the hose return line, the connector or the line feeding the connector, as well. Let me know via a comment if there is anything else I can help you with relating to this repair.

HostgatorMemberFor the money, the best engine oil for a high-revving 660cc engine is a true synthetic like Mobil 1. The reason I advocate a synthetic is quite simple: a true synthetic is engineered from the start to work in high-stress, high-temperature situations that leave other oils breaking down.

A true synthetic is blended so that it uses complete carbon chains to do its work. Not only are the chains engineered to slip easily past one another, but they are also built to handle the heat because they are full carbon rings.

A standard mineral-based oil like a good 5W-30 works up to a point. It is thin and has good short-term wear characteristics but you will find that after a relative short time, depending on the service your 660 is in, the oil will start to break down, leaving you with little more than a black mess in the oil sump.

A synthetic, on the other hand, easily stands up to the heat and wear high-revving and temperatures bring.

I know that where you live 5 quarts of Mobil 1 may be expensive. It is, after all, a premium commodity. That said, because you choose that particular synthetic, it means that you care about your engine and vehicle and want to give it the best chance you can.

HostgatorMemberAfter doing some checking, I came up with a couple of ideas about your problem. The cause is likely either a switch in the case that monitors tranny fluid level. If it goes, then it puts you Toyota into limp-home mode. The second cause is the transmission fluid level.

I would suggest getting your Corolla over to a dealership and have the CVT looked at closely. Have them replace the level monitor switch. Be sure that once the switch is replaced that the fluid is replaced with the proper fluid. Be sure to replace the filters, as well.

If this doesn’t fix the problem, then I am afraid you may be looking at major transmission work. Since the CVT is essentially one big gear you are looking at a major tranny replacement that could cost about $3,400.

I know it seems like your options are limited. However, with CVTs there isn’t much to replace as many of the subsystems are sealed and they have to be replaced by swapping out the old CVT for a remanufactured on.

HostgatorMemberThe question I have is why didn’t the service facility act on the information it had and repair the problem? Did you authorize the repair? I know that BMWs are incredibly expensive to repair, but I would have thought that if a shop does the diagnostic and gives you the results it should have done the repairs, as well.

I honestly think I know the answer and it is simply that the shop might be overwhelmed with other work and the amount of time needed to run each line in the loom from source to termination can be enormous. And, even if they were to do the work they might find that by the time they have finished doing the work you would be into a very four-figure repair bill ($2,000-#3,000). So, that I suspect is why the bounced it back to you.

With that said, though, if you have to do the work, I would start with the solenoids first. The X5 uses a six-speed transmission and that means there are three solenoids tucked up on the valve body, one on the inside and two on the outside. Here’s the way to work this:

Locate the power leads and their colors at the base or top of the device — there are usually four to six wires per device. Once you have located the color, check for continuity by setting a volt-ohmmeter on the RX1 setting, placing one test probe on the appropriate wire color and terminal on the loom and then placing the other probe on the similarly colored wire and terminal. Be sure the circuit is de-energized or else two things will happen, you won’t get your reading and you will be out a VOM as it will destroy the meter.

Yes, it will take time and you will have to open up the valve body to get to one of the solenoids and do those tests. However, I suspect when you are finished you will have found the offending wire so you can replace it or find the place where it is worn and chafing or open and you will have repaired it. In doing so, you have saved yourself a whole bunch and fixed the problem. Please let me know what happens so I can share this with others.

HostgatorMemberI don’t think you will have to. You have done all the right things so far, but have you reconnected all the electronic lines correctly. If reverse just one of them when you are wiring things back up and say go white to green instead of green to white, you will have a Silverado that won’t move at all. It’s just that simple.

And while it is just that simple, it is a lot more complex, too. The reason again is electronic. Have you checked to make sure the sensors are also installed correctly. It is all too easy to turn a sensor over and put it 180-degrees out of phase. In other words, it’s not going to work. What sensors might be involved in this? To name a few, there’s the throttle positioning sensor; the manifold air pressure sensor; the mass airflow sensor and then there’s also the solenoid pack. If it isn’t energizing correctly (it has put in backwards), then your pickup won’t move now matter what gear you drop it into.

The thing about electronics is this: while the functions it controls are simple in concept, their actual interactions are complex and just finding where a wire might be chafing and shorting or open is a long process that involves testing segment after segment of a circuit.

I’d pickup the electronics service manual and take a close look at the sensors used, the control modules used (they have their impact, too) and then walk through a circuit to see just what it would take to troubleshoot. Or, you can go to a service area that has a network analyzer (no not internet), a device that shoots a voltage down a wire and waits for a return. If there is no return, it can figure out from the time-travel figures where the device or wire may be going down. All either you have to do or the tech at the service area has to do now, is go through the miles of wire to find the specific problem and then rewire things appropriately. I hope this helps. Let me know what happens.

HostgatorMemberI have to assume that you are driving a Ford Taurus that was built sometime in the last decade because that does a great deal to explain your question. Getting to the root of the problem, it has to deal with the computer setup in your Taurus.

In every modern vehicle (car, truck, SUV), there are a number of computers controlling everything. Indeed, there are very few mechanical systems controlling things anymore. For example, the transmission is controlled by a computer called the Transmission Control Module (TCM). The TCM reports directly to the Engine Control Module (ECM). However, it also takes directions from the Powertrain Control Module (PCM), the Fuel System Control Module (FCM), as well as from the Brake Control Module (BCM), and others.

In turn, each of the other control modules not only listens to the others on the CAN (Car Area Network) but also to the ECM as they pass information and instructions back and forth.

Tying everything together is the CAN which serves to bind the engine electronics together so each control module acts when it has to or passes information on to other systems. You see each control module — there can be from eight to 15 controlling an engine — have a number of subsystems reporting to them. the subsystems are usually sensors. However, there may be a number of activators turning things on and off in response to the information provided by the sensors.

If this seems like a complicated information web, it is. Because it is and because it is electronic, there are times when orders from the boss (PCM) can be delayed or broken up. The transmission is a good example.

At one time, the transmission was mechanically controlled. You pulled down on the PRNDL lever and a cable in a carrier started the process that ended up in the car going into gear mechanically. Everything else was also mechanically controlled, including step-downs, gear choice and the like.

Now, the ECM, after listening to all of the subsystems on the CAN, as well as the sensors, determines how the transmission reacts. You start things off by selecting a gear, D(rive) for instance. Next, the ECM lines things up to answer your request. Let’s say a glitch happens in the “shift-by-wire” transmission. What happens then? It’s quite possible the indicator may read R(everse) while the transmission is Drive. That’s the answer to your question. It’s all the result computer control not reading things correctly.

HostgatorMemberYou’re in luck, to this point, because your Veloster is relatively new — in model years — so that it features a fairly up-to-date engine control module (ECM). With that said, though, I think your trouble lies right there, the ECM. You will have to have this confirmed by having a diagnostic run by your dealer or a good shop with up-to-date software.

Now, without running the diagnostic myself, I can’t tell you what the exact problem might be but what I suspect has happened is that the ECM has gone into a loop and is refusing to communicate with any of the subsystems or sensors linked to the subsystems as well.

This means that when you put your foot on the accelerator instead of moving out nicely or even poorly — except very poorly — the subsystems connected to the pedal are in what you might call a large-sized quandary. It is asking the ECM for instructions and, since the ECM is essentially talking to itself and not taking any input, the engine defaults to a combination of limp-home mode (that’s the high-revving, low-speed alternative you mentioned — it’s there so you can get your Veloster either home or to a service area) and “deafness,” where it doesn’t hear from the subsystems or sensors and then just runs away.

My suggestion to you would be to drive the Veloster into a service area and have the technicians run the OBD-II diagnostic with the latest software if they have it. Then, using the codes that are likely to be thrown (likely to have the starting code structure p07XXX for transmission-related failures) will tell your technician where to look. I would further suggest that if you want the latest Hyundai-approved software so your codes would be far more precise in their error information so your techs will be able to find the problems quickly and fix the issues.

One last suggestion, for what it is worth. When was the last time you had the transmission fluid changed? It’s possible that the tranny, even though it’s a manual, could have very dirty transmission fluid and, as a result, it isn’t working correctly. I’d have the transmission fluid drained (not blown) out and swapped with new fluid and then see what happens. I would say, at this point, that this may be a long shot, but it is worth the $39.95 or so to have it changed. If things start to work correctly, you may have saved yourself hundreds. Let me know what your technicians find, would you? I like sharing with our readers so they can see what happens as the problems are remedied.

HostgatorMemberI think you have hit the nail on the head. The continued p0753 code does indicate that Solenoid A, which controls the first two speed selections for the transmission, is bad, but, here’s the issue: why does the code keep popping?

There are three possible reasons:

- A burned out wire

- A chafed wire

- A bad connector

Suffice it to say, wires burn out. And, since the solenoid is an electronic device, linked to the electronic system in your Monte Carlo by wire, it is very possible for a wire to burn out, given the age of your Chev. It is, after all, 22 years old and the fine magnet wire used for the solenoids and other sensors, over time, can get brittle and break. Or, it can burn out due to overvoltages. I would start at the wire loom connecting to the solenoid pack, checking the signal (voltage) on each wire and then following each wire into the vehicle as far as you can go. Hopefully, you will be able to trace each test point to the source. It will take time as miles of wire are used in each vehicle, however, there’s nothing else for it. There are some very expensive testers out there that will power a de-energized circuit that will find out where breaks or burnouts might be.

Besides burnouts, wires can also short out because wires have chafed against each other or they may have chafed against an exposed screw head or the body. Or, wires can go open — which appears like a short — and the electricity will stop flowing, as well.

Finally, the crimp terminal at the base of the solenoid may have worn to the point where it has gone short and you may not even notice it because the wire still appears to be in good shape. The only way to test this is to place a volt-ohhmeter in the 13.8 volt position, hook one wire to ground and then probe the wire at the base and on the connector. If there is a test point available, test there too. Try to find where the voltage — hence the device — is failing.

One thing to remember if this is the problem, if you have to replace any wires, it it best to route from source to the device. That is not an inexpensive proposition. And, since there are roughly 36 possible combinations to troubleshoot before you get to the right wire or wires, it will take you time. And rewiring will cost you money. If you cn do it yourself, then, you will save up to $150 to $200 per wire. If it is simply a connector that should cost about $75 to troubleshoot and replace.

HostgatorMemberFirst things first, your Chevy is running in limp-home mode. The way your transmission is reacting is telling me that there’s something very basic and, potentially, major going on. Normally, limp-home mode comes on when something major fails — the torque converter or impeller or perhaps the input shaft or its bushings or the clutches/bands and gearing or a combination of several of the items.

Limp-home mode gives you the ability to drive your Chevy home and then to a dealership or repair shop the next day for transmission work. It is not a long-term solution. In other words, it is meant to get your Chev in for repairs. By driving it continually in limp-home mode you are further damaging the transmission, which is a very big no-no.

Here’s something you can do to help your technician find a quicker answer to your problem, run a diagnostic. There are several very good generic OBD-II scanners on the market. All you have to do is plug it into the diagnostic port at the left lower part of the dash panel and let it collect data. Then, take the scanner to your dealer or repair shop and have it read. It should point out the area that is failing and give you a good jump on finding the proper solution.

There is one possible alternative: check to see if the solenoid for second gear is stuck. If it is that will make things much easier on your pocketbook. You can get that information from the diagnostic scan.

HostgatorMemberIt sounds to me like you are having a solenoid problem. The solenoids ensure that your transmission switches from gear to gear cleanly and holds that gear until the conditions change and powertrain either downshifts or upshifts.

At one time, an automatic transmission relied solely on mechanical means to shift — bands/clutches, gears, torque converter and the rest — and that was it. As more precise shifts were required both for the best mileage as well as top emissions, the automakers began using electronics to take over the jobs that the mechanical devices handled.

For example, instead of relying solely on the clutches and bands and gears to make sure the right combinations were selected, today’s transmission uses a series of electronic sensors — the throttle position sensor and mass airflow sensor, as well as others — plus a number of solenoids and the valve body to ensure that the right gearing is chosen.

Let’s assume, for example, that your Mustang is shifting from 1st to second. At one time, it would take a combination of the right rpm point from the torque converter plus the clutches picking the right gear timing the upshift through the use of the clutches bands and valve body, to make sure the upshift happened. For years, it worked reasonably well, but it wasn’t precise.

As more precision was needed, the automakers added sensors that watched, among other things, the position of the throttle, the pressure flow through the manifold, as well as the air flow at the intake. There were also sensors at the wheels and on the crankshaft watching to make sure everything was in sync for the proper upshift.

Successful upshifts are enabled by a number of solenoids or switches that divert the transmission fluid through the proper galleries in the valve body. All of this must work properly to make sure your car upshifts and downshifts correctly.

Now, you have lost third gear and the way it is acting, it is likely the solenoid is either sticking or has failed completely. I would run a diagnostic looking for the right codes that indicate a solenoid failure and I believe you will find the OBD test will show you which solenoid has failed.

You will find the solenoid packs are located externally on the valve body or internally. If it is an internal solenoid, you will have to pull the valve body, which means a partial transmission teardown and replace the proper solenoid pack. If it is external, which it may well be, then you are looking at simply swapping the proper pack yourself.

If you can repair it yourself, you are looking at about a $200 investment for the part. If you have to have a technician tear things down far enough to get to the internal solenoid, you are looking at about a $1,200 bill.

I hope this helps. Please let me know what happens as I would like to share your outcome with our readers.

HostgatorMemberYup, it is a transmission issue, but, it isn’t what you might think. Your 2006 Expedition has a complex suite of electronics that run the transmission. For example, the engine control module (ECM) is the master computer of your engine. It not only records issues as they occur, much like a good digital tape recorder, but it also takes input from as many as 16 different sensors, control modules and the like. The ECM, on receiving all of its inputs, determines exactly how your transmission will set up and operate.

For instance, if the manifold air pressure (MAP) sensor sends information to the ECM suggesting that not only do the transmission settings need to be tightened but also suggesting that the fuel-air requirements for the fuel-injection system need to be tightened as well, then not only will the tranny operate more efficiently but the ignition system will do so as well. Think of it, the tranny helped to determine how the engine should work, as well as the transmission.

The same is true of the MAF or mass airflow sensor. Indeed, there are sensors at each wheel, watching the crankshaft and the transmission, as well as ignition system and more that keep your Expedition running correctly.

What I suspect is happening here is that that ECM is on its last legs and has to be replaced. At one time you would have to step through a whole range of diagnostics to figure out what is happening in the transmission because transmissions, at that time, were primarily mechanical and the control systems were mechanical. With today’s computer technology and the extensive use of sensors and CPUs to keep things working correctly, it is fairly easy to diagnose the area where a problem may be occurring.

That’s why I pointed to the ECM because of the reaction of the transmission. To figure out the exact sensor or control module that might be responsible, you still do have to go back to the basics and run a diagnostic scan and then go through the results printout to see where you should be checking. Let me know what happens, I’d be interested to learn.

HostgatorMemberHere’s another thought. At one point, your question makes it sound as if this is a dual-shift-type of transmission. That is, you can run through the gears or let the transmission do it for you. Now, I won’t change my thinking on the automatic side of the transmission, however, on the other side, I would suggest you look closely at the gearing and related mechanicals. It is possible that dog collar is slipping. It is the device that ensures that when you have chosen the gears not only go home but that they remain there. If it is slipping then your transmission just won’t work correctly. It will, in fact, do much as you describe.

And, one other area to check is the clutch plate, friction plate, engine interface. It’s quite possible the plates are locking up, rather than slipping (it does happen in a small number of vehicles). When it does, it is also possible that your BMW will act as you describe. Just an added thought.

HostgatorMemberFor whatever reason, your BMW has gone into “limp-home” mode so that it will only work on low gear and, perhaps, in reverse, as you indicate. “Limp-home” mode is there so that you can get your car either to your driveway or to a service area. If you are able to get home so that you can contact your dealer and a tow or ramp truck, then you can have your car taken to a repair shop or dealership for work. Many drivers, though, when they find their BMWs, in “limp-home” drive directly to their dealers so they can have their transmissions repaired.

Why has this happened? That’s a good question. It could be something simple as a plugged transmission filter to something as major as a Transmission Control Module and related software failure. In either case, the tranny has gone into “limp-home” mode so you can get it to service.

That’s about all I can tell you because there’s not much more information to go on.

HostgatorMemberActually, you have hit the nail on the head, though you probably don’t know it. You said your 2000 Durango will start and run but it won’t go anywhere and that there’s no display in the LCD display on the dash. That’s what gave a major clue about your Durango’s problem. The other clue was the shorting wires at the transmission pressure sensor. You replaced the wires and connector, as well as the sensor, but you did not go far enough.

You should have obtained an OBD-II diagnostic tester and run a full series of tests to see where other problems might lie. Granted, the generic OBD-II testers that are out there will only point to general areas because they use very generic software drivers. Unless you have access to a Dodge ODB-II tester and up-to-date manufacturer-backed software, then generalities are all that is possible. Specifics are generated by the Dodge-backed ODB-II diagnostic tester.

Once you have obtained your diagnostic results and you have printed them out, look at them closely to see what might be going on with the Engine Control Module (ECM). I am willing to bet you a candy bar that you won’t see any results for the ECM. Indeed, you might see error codes that point to a problem with the ECM, but that’s about as specific as it will get.

The reason is this (it relates to the problems you identified earlier with sensors) at some point your Durango must have experienced a major electricity spike running through every major system. It might have been generated by a static electricity spark (lighting, for example) nearby or it might have been generated when a wire connected to the ECM shorted and took out the module.

Without the software that it pushes out to electronic parts like the display, there is nothing to provide the various control modules and systems with instructions and so your Durango is effectively left high-and-dry.

For example, if there is no PRNDL display in the LCD on the dash, the Transmission Control Module (TCM) that takes its instructions from the display as to gearing and movement has no driver software telling it what to do. The result is the transmission won’t work.

You see, in drive-by-wire systems like your Durango’s transmission even if you can shift into a gear, how is the TCM supposed to tell what gear it might be?

That’s the problem and the only solution is replacing the ECM with a brand-new one from the box. At the same time, your SUV needs to be reprogrammed so that all of the libraries that it depends on for its functionality can be accessed. As it is now, you just have an SUV that can’t get from A to B because it doesn’t know which gear you want to access and whether you want to do it frontways or backwards. The cost for this will be in the range of $1,250, depending on where you obtain your new TCM (salvage yards can help) and how much the software load will be.

HostgatorMemberSomething just struck me as I read your answer to my last suggestion and it is this: Can you afford to take the Dayz into a service shop to have the engine looked at? You keep telling me the engine is noisy and I am wondering if there may not be a mechanical problem for your Nissan’s problem?

If you can, I would take it over to the service area and have the entire driveline, including the engine, looked at and it could be that the problem is there.

HostgatorMemberThanks for the update, it gives me a bit more to go on. Here’s what I would suggest. You mention that it “goes uphill” and sometimes works “with the AC on.” That tells me that there is some life in the CVT and that it may just be possible to revive things with a bit of work.

My next suggestion is to either get an OBD diagnostic tester and plug it into the diagnostic plug near the kick panel. I would then suggest running the car for a time in whatever modes you can to make it move so that we can get some information about what ails the transmission. The OBD tester — they are available very inexpensively — should give you a range of codes that should, at least, give you an indication of where the problem is.

From my experience, it sounds like there are several problems confronting your Nissan. It is more than likely more than one set of gears in the main body of the transmission are shot. The good news is that they can be rebuilt with time and patience. The bad news is that it will tie up your Nissan and it can get costly — though likely less than a new CVT — if you have to rebuild very much more than half of the transmission’s main parts.

Again, your first step has to be a diagnostic one so you can see what might be going on. Your next step should be getting a qualified technician involved who can read the diagnostic codes or who has the software that can read the codes. Then, you can set up a strategy for your Nissan’s repair with the tech.

Now, I don’t know exactly how much of your CVT is salvageable but you may be lucky and find it is not as bad as it seems. It’s just that you need someone to get in there with you to not only give you the information you need but also to get you going in the right direction with repairs.

HostgatorMemberIf you swapped out the gearbox are you saying that you swapped out the CVT?

As they say, this is a teaching moment. I feel bad that you used the wrong transmission fluid for your Nissan but I do have to tell you that when the automaker tells you to use, say, Dexron, for instance, you use Dexron, you don’t use anything else. There is a reason for the instruction and the reason is that the transmission and the transmission fluid are meant to work together.

If you put in the wrong fluid, then you risk damaging or destroying the entire transmission. I can understand how it is possible to go to an auto parts store and ask for transmission fluid and having the clerk point to a rack of fluid as he is busy trying to answer the phone and other customer questions. And, you, perhaps not knowing that there are specific types of fluid made for continuously variable transmissions (CVT) just pick up a bottle or two of fluid labeled “transmission fluid,” figuring you can use it.

Unless it is labeled CVT transmission fluid then you can’t use it in your vehicle. What I suspect happened next is that your transmission, not having the proper fluid to not only protect it but also make it operate properly and to lubricate it as well, slowly began to destroy itself from within.

More than likely all of the speed-specific bands that tighten, providing the continual linkage — they loosen when the particular gearing isn’t used, though most of the time the entire drivetrain is engaged — needed are no longer working correctly and you now have a vehicle with an engine and wheels and the whole nine yards. The only problem is that like a vehicle with a normal transmission that has gone your Nissan is just sitting there engine on with nothing happening or nothing much happening.

Now, I can’t honestly say what mechanical damage may have been done to the engine. However, I can say this much and it is that you had better think that it’s likely you will have to replace the entire CVT, at a cost of about $4,000. There’s nothing much else for it, except another vehicle, but, I don’t think you need not go that far. A rebuilt transmission should take care of things.

HostgatorMemberThough it could be one of several possibilities, I think the most obvious choice here is the torque converter and or the impeller. The torque converter is the part of the transmission that gets everything going as it spools up to operating speed and begins sending transmission fluid toward the impeller when then sets up the current that circulates through the tranny case.

What I suspect happens is that given the age of your Camaro and, even if you’ve driven conservatively it’s still likely 15,000 miles per year. This means your Camaro has upwards of 300,000 on the odometer. Now, I don’t know how often you have the transmission fluid and filter swapped out and replaced as well as the tranny filter, but, I have to suspect that given the age and possible mileage on the Camaro, the transmission — it’s one of GM’s stalwarts — that the transmission is giving up the ghost.

The torque converter is one of the first parts that goes. And, since you also heard a rather large clunk I suspect that the impeller may have also bitten the dust. Between the two, you are either going to pay a fortune to replace the items — roughly $3,500 — or you are going to have to bit the bullet and drop in a rebuilt for $4,000.

Why would I make this suggestion? After, it would seem that if it is only a couple of discrete parts, then it would be cheaper to replace them. It might look that way on the surface, but when you get into it, the transmission is like an independent ecosystem. Every part is interdependent on the parts earlier in line. Now, if the torque converter/impeller combo is shot and you replace only those devices, then it is only a matter of time — I can almost guarantee it — before the next piece in the chain breaks and leaves you high and dry again. Instead of paying a king’s ransom to replace the parts individually, it is best to drop in the rebuilt. And, why would you wait until the next part fails before you replace it?

HostgatorMemberThis is one where I have to agree with the dealer. On an AWD vehicle like your Mazda, there are two shafts from your transmission, an input shaft, and an output shaft. The input shaft takes the engine’s rpms and turns it into usable power for the transmission’s torque converter. Once the torque converter spins up, it transmits that power to the impeller and then it goes into the valve body and solenoids where the proper gearing is chosen. Once that “decision” point is reached, the proper gearing is chosen and that is output to the clutches and bands which take the power and send it to the other shaft, the output shaft.

The output shaft drives the universal where the power is then converted so it can be used to drive the half-shafts to the front wheels or the shaft that drives the rear differential and the rear wheels.

From the sound of your problem, it seems to me the input shaft is out of round and working eccentrically when your foot is on the brake. When you release the brake the shaft runs more normally because of the centripetal force that pushes it toward the gears on the side of the input gallery. then when you put your foot back on the brakes the eccentricity shows up again and there’s that vibration.

The only way around this, aside from stripping the entire unit down — a very costly project — and replacing the input shaft and gearing that may have been forced out of round, as well as the shaft bearings and bushings, is replacing the transmission and transfer case because they are a single unit in an AWD vehicle. Yes, it is costly, roughly $3,400 to $4,000, depending on labor rates. But, if you want to keep your Mazda on the road, then there’s no way around it. Or, you can accept the vibration and drive on until something snaps due to that vibration. It won’t be today or tomorrow but sometime in the near future I suspect there will be a problem that could bring not only the vibration but your Mazda to a dead stop, hopefully not in the middle of traffic. Do yourself a favor and do the work or trade out of the CX9 into a newer model.

-

AuthorPosts

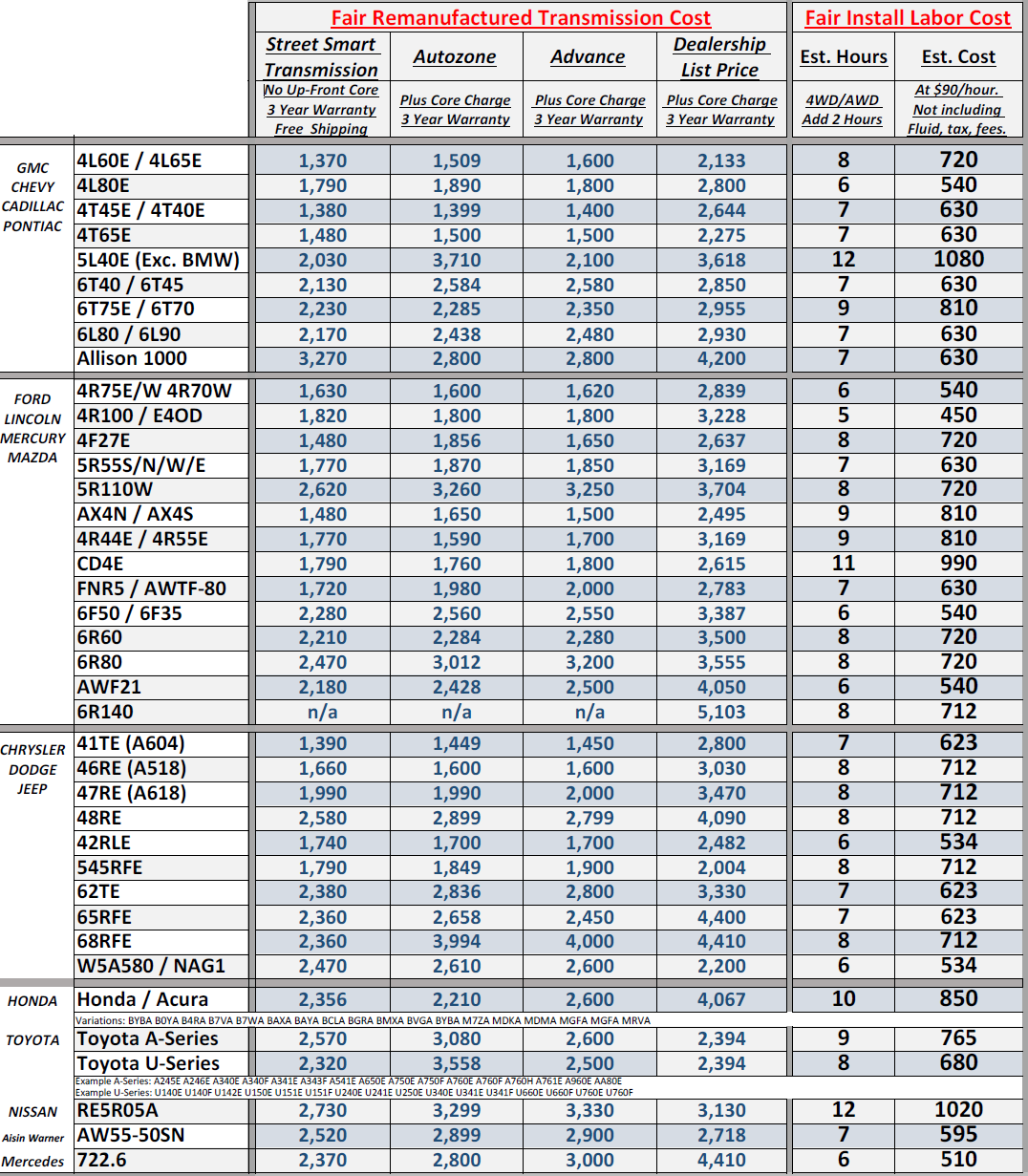

Fair Replacement Transmission Cost by Vehicle

- Use the Year / Make / Model lookup tool to determine what transmission your vehicle has. [transtar]

- Find your transmission model in the table below for fair prices from reputable suppliers. Also fair labor cost for local installation at a local auto repair shop.

- Get a free estimate on a remanufactured transmission by email.

Fair Remanufactured Transmission Price Ranges by Transmission Model Updated May 1, 2018