In This Guide

- Vehicle Compatibility – Makes & Models

- 4L65E Model Name Explanation

- 4L65E Transmission Overview

- 4L60E vs. 4L65E

- Is It Possible to Upgrade?

- Problems with the 4L65E

- History of the 700R4, 4L60E and 4L65E

- Remanufactured 4L65E Transmission Updates and Upgrades

- What’s Included

To get an estimate on a 4L65E, click Get a Free Estimate.

What Transmission Do I Have?

Replacement 4L65E Transmission Prices:

| Transmission | Street Smart Transmission |

|---|---|

| 4L60E / 4L65E | 2100 |

Vehicle Compatibility – Makes & Models

- 2005 C6 Corvette

- Cadillac Escalade

- Cadillac Escalade EXT

- Chevrolet Silverado SS

- GMC Sierra Denali

- GMC Yukon Denali

- Hummer H2

- Holden Crewman 2004 Only

- Holden One Tonner 2004 Only

- 2005–2006 Pontiac GTO (M32, 3.46:1 final drive)

- 2002 Isuzu Axiom

4L65E Model Name Explanation

Every GM transmission has a specific model number used to denote its capabilities and performance. Here’s what they translate to for the 4L65E. The 4 means that there are 4 forward gears. The L indicates that the transmission is longitudinally mounted; that is, along the axis of the vehicle. This works best for rear-wheel drives. Conversely, transverse mounts for front-wheel drives are indicated with the letter T.

The 65 denotes the rating of the vehicle’s torque; at 65, this is about 360 foot-pounds, the higher the torque is the stronger the transmission becomes. Finally, the E means the transmission is controlled with an onboard computer. This allows more precise shifting cues.

4L65E Transmission Overview

The primary building location for the 4L65T is the Toledo, Ohio transmission factory, Other locations that see these transmissions build include the city of Romulus in Michigan and Ramos Arizpe in Mexico.

The 4L65E appeared in 2001 as an update to the 4L6-E and was placed behind the 6.0 Vertec engine. The 4L65E could withstand up to 380 pound-feet of torque due to several enhancements. It included five-pinion front and rear planetary gears and placed another clutch in the input housing. Therefore, there were 7 clutches total.

Finally, it used an induction-hardened shaft assembly, which was superior to standard heat treating of metals. As updates progressed, GM engineers experimented with pairing the transmission with different motors.

The 4L65E is the most robust transmission of its type and can, therefore, serve many different types of vehicles. For example, the lowered ratio for first gear appeals to off-road drivers because of rough terrain.

Meanwhile, the overdrive capacity wins out for standard street drivers due to the decreased gas usage in start-stop scenarios. One could find the 4L65E in SUVs like the Hummer or in racing vehicles like the GTO. Even standard pickup trucks employed this transmission. Any of these vehicles could be expected to, in one way or another, suffer more stress than a vehicle driven under normal road conditions. Therefore, they need a stronger transmission, which the 4L65E provides.

4L60E vs. 4L65E

One of the first ways to tell the earlier model from the later one is by looking at the bell housing. The 4L65E has a seven-bolt housing, whereas the 4L60E has only six. If you have a ruler on hand, you can also measure the depth of the bell; the 65E has 7 inches of depth whereas the 60E has only 6.5 inches. Finally, the 4L65E employs an input shaft that is 300mm wide. It and the torque converter work only for LS vehicles.

Here are a few more defining characteristics.

- Input and reaction gears have five pinions, rather than the four seen in the 4L60R

- Stator shaft splines are heat-treated for extra endurance

- Turbine shaft is induction-hardened, allowing for more robust performance

- Low-gear and reverse have a more robust roller clutch to prevent loss of control in the vehicle

- The 3-4 clutch received another friction plate

- Output shaft shot-peened for extra security.

- Valve body shaft was calibrated to accommodate extra load and prevent fluid leakage.

The extra pinion on the gear increases the lifespan of the gear by spreading out the workload. Being made of powdered metal also supposedly improves the accuracy and measurements, as well as making the gear stronger than if it were made of non-powdered metal.

The 4L65E has an induction-hardened turbine shaft. This component has to be able to take high amounts of stress and can do so because of induction hardening. This process involves passing an electric current through the metal during the heat-treating cycles. The electric current creates a slight magnetic field that realigns the molecular structure of the metal and increases its strength.

In addition to the gear changes and different material treatments, the L65 switches out the rollers in the roller clutch. Their larger diameters add to the load they can handle. The same goes for the extra plate that was added to the 3-4 clutch. Third and fourth gears are the gears people drive in when in city and highway traffic and therefore the ones in which the vehicle sees the most use

Problems with the 4L65E

Most drivers have little issue with the 4L65E. The only major problem is the wide gear ratio between first and second gear; 3.06:1 and 1.62:1 respectively. This makes a rougher transition at those speeds. However, it is possible to modify the transmission on some vehicles.

History of the 700R4, 4L60E and 4L65E

Throughout the 1980s, GM used the Turbo Hydra-Matic 700R4, but it was phased out of circulation with the 1993 Camaro and Corvette models. GM renamed the TH700 to the 4L60 in 1990, and it lasted in that form until 1992 with the introduction of electronic components that replaced pure hydraulics. The valve body received an additional check ball

The 4L60E needed electronic controls to perform shifting and only appeared in 1993 for rear-wheel drive passenger vehicles. It wasn’t until 2001 that the 4L60E was updated to the 4L65 E and 4L70E.

4L65E Diagnostic Trouble Codes | DTC

| Trouble Code | Description |

|---|---|

| P0706 | Transmission Range Sensor Circuit Range/Performance |

| P0711 | Transmission Fluid Temperature Sensor Circuit Range/Performance |

| P0712 | Transmission Fluid Temperature Sensor Circuit Low Input |

| P0713 | Transmission Fluid Temperature Sensor Circuit High Input |

| P0719 | Torque Converter/Brake Switch B Circuit Low |

| P0724 | Torque Converter/Brake Switch B Circuit High |

| P0740 | Torque Converter Clutch Circuit Malfunction |

| P0748 | Pressure Control Solenoid 'A' Electrical |

| P0751 | Shift Solenoid 'A' Performance or Stuck Off |

| P0753 | Shift Solenoid 'A' Electrical |

| P0756 | Shift Solenoid 'B' Performance or Stuck Off |

| P0757 | Shift Solenoid 'B' Stuck On |

| P0758 | Shift Solenoid 'B' Electrical |

| P0785 | Shift/Timing Solenoid |

| P0894 | Transmission Component Slipping |

| P1860 | TCC PWM Solenoid Circuit Electrical |

| P1870 | Transmission Component Slipping: GM Transmission |

4L65E Technical Service Bulletins | TSBs

TSB 01-07-30-002C – Transmission stuck in third gear with inoperable instrument cluster and multiple DTC’s – 4L60E Transmission & 4L65 Transmission

1999 – 2003 Cadillac Escalade – 2002 – 2003 Cadillac Escalade EXT – 2003 Cadillac Escalade ESV – 1997 – 2003 Chevrolet Silverado – 1997 – 2003 Chevrolet Suburban – 1997 – 2003 Chevrolet Tahoe – 1997 – 2003 Chevrolet Blazer – 1997 – 2003 Chevrolet Express – 1997 – 2003 Chevrolet S10 – 2002 – 2003 Chevrolet Avalanche – 2002 – 2003 Chevrolet Trailblazer – 2002 – 2003 Chevrolet Trailblazer EXT – 1997 – 2003 GMC Sierra – 1997 – 1999 GMC Suburban – 1999 – 2003 GMC Yukon XL – 1997 – 2003 GMC Yukon – 1997 – 2001 GMC Jimmy – 1997 – 2003 GMC Savanna – 1997 – 2003 GMC Sonoma – 2002 – 2003 GMC Envoy – 2002 – 2003 GMC Envoy XL – 1997 – 2003 Oldsmobile Bravada

Problem – Vehicles equipped with the 4L60E and 4L65E transmission may become stuck in third gear, the instrument cluster may not function, and the following DTC’s may be set: P0740, P0753, P0758, P0785 and P1860.

Solution – The most likely cause of this transmission problem is a blown fuse or an open on circuit 1020 between the fuse panel and the transmission. If no battery voltage is found at the fuse, the ignition switch will need to be replaced

TSB 04-07-30-028A – Transmission fluid leaks from reverse servo cover – 4L65E Transmission

Problem – Transmission fluid leaks may be observed under the vehicle, which may be caused by a 4L65 reverse servo seal that can actually shrink in the cold weather below 20°F/-6.7°C

Solution – Replace reverse servo cover seal

TSB 01-07-30-038D – Poor transmission performance/slipping with P0757 DTC – 4L60E Transmission – 4L65E Transmission – 4L70E Transmission

2003-2007 HUMMER H2 – 2006-2007 HUMMER H3 – 2005-2007 Saab 9-7X

Problem – Drivers may experience the loss of 3rd and 4th gear, erratic shifting, slipping, freewheeling above 30 mph and a P0757 DTC.

Solution – In order to repair this transmission problem, the 2-3 shift valve, 2-3 shuttle valve, and the valve bore will need to be cleaned of any debris. The 2-4 band and/or 3-4 clutches may also need to be inspected and changed.

TSB 08-07-30-027 – No movements when transmission is shifted into Drive or third – 4L60E Transmission – 4L65E Transmission – 4L70E Transmission

1982-2005 GM Passenger Cars and Light Duty Trucks: 2006-2007 Buick Rainier – 2006 Cadillac Escalade, Escalade ESV & Escalade EXT – 2006 Chevrolet SSR – 2006-2008 Chevrolet Avalanche – 2006-2008 Chevrolet Colorado – 2006-2008 Chevrolet Express – 2006-2008 Chevrolet Silverado Classic – 2006-2008 Chevrolet Silverado – 2006-2008 Chevrolet Suburban – 2006-2008 Chevrolet Tahoe – 2006-2008 Chevrolet TrailBlazer – 2006 GMC Yukon Denali – 2006 GMC Yukon Denali XL – 2006-2008 GMC Canyon – 2006-2008 GMC Envoy – 2006-2008 GMC Savana – 2006-2008 GMC Sierra Classic – 2006-2008 GMC Sierra – 2006-2008 GMC Yukon – 2006-2008 GMC Yukon XL – 2006 Pontiac GTO – 2006-2007 HUMMER H2 – 2006-2008 HUMMER H3 – 2006-2008 Saab 9-7X – with the 4L60, 4L60E, 4L65E or 4L70E Automatic Transmission (RPOs MD8, M30, M32, M33 or M70)

Problem – It is possible to experience no movement when the transmission is shifted into Drive or the 3rd gear position. It is possible to experience normal operation when the transmission shifted into second, first or reverse.

Solution – Replace the forward sprag assembly

TSB 00-07-30-022D – No reverse, second or fourth gears – 4L60E Transmission & 4L65E Transmission

1993 – 2005 GM passenger cars and light duty trucks

Problem – Drivers may experience the loss of reverse, second and fourth gears. First and third gears will seem to function normally

Solution – The reaction sun gear may fail inside of the sun shell. It will need to be replaced with a stronger heat-treated 4L60E / 4L65 sun gear.

TSB 01-04-17-004B – Clunk, bump or squawk when vehicle comes to a stop, or when it is accelerating from a complete stop – 4WD/AWD vehicles with a one-piece propeller/drive shaft only

1999-2004 Cadillac Escalade, Escalade EXT, Escalade ESV – 1996-1999 Chevrolet 1500 Series Extended Cab Short Box Pickup (Old Style) – 1996-1999 Chevrolet 1500 Series Regular Cab Pickup and Utility Models (Old Style) – 1999-2002 Chevrolet Silverado Extended Cab Short Box (New Style) – 1999-2004 Chevrolet Silverado 1500 Series Regular Cab (New Style) – 2000-2004 Chevrolet 1500 Series Avalanche, Suburban and Tahoe – 2001-2004 Chevrolet Silverado 2500/3500 Series Regular Cab with Long Bed or Extended Cab (New Style) – 2001-2004 Chevrolet Silverado 2500 series crew cab, short box (New style) – 1996-1999 GMC 1500 series extended cab short box (Old style) – 1996-1999 GMC 1500 series regular cab pickup and utility models (Old Style) – 1999-2002 GMC Sierra extended cab short box (New style) – 1999-2004 GMC 1500 series Yukon, Yukon XL – 2000-2004 GMC Sierra 2500/3500 series regular cab with long bed or extended cab (New style) – 2001-2004 GMC Sierra 2500 Series Crew Cab, Short Box (New Style) – 2003-2005 HUMMER H2

Problem – In vehicles equipped with 4WD or AWD, drivers may experience a clunk, bump or squawk noise when they come to a stop, or when accelerating from a complete stop. This may occur during the 2-3 upshift or 3-2 downshift.

Solution – Replace the rear driveshaft slip yoke with a more robust nickel plated slip yoke.

TSB 06-07-30-007A – Harsh 1-2 shift with P0894 DTC – 4L60E Transmission | 4L65 Transmission | 4L70E Transmission

2006 Cadillac Escalade Models – 2006 Chevrolet Light Duty Trucks – 2006 Chevrolet Express Vans – 2006 GMC Light Duty Trucks – 2006 GMC Savana Vans – 2006 Pontiac GTO – 2006 HUMMER H2, H3 – 2006 Saab 9-7X – with 4L60-E / 4L65-E / 4L70-E (RPOs M30, M32, M70) Automatic Transmission

Problem – Drivers may experience an unusually harsh 1-2 shift with a P0894 DTC

Solution – Replace the TCC enable solenoid and/or wiring harness

TSB 08-07-30-008B – Diagnostic information for P0894 and P1870 DTC – 4L60E Transmission | 4L65 Transmission | 4L70E Transmission

2003-2007 GM Passenger Cars and Light Duty Trucks – 2003-2007 HUMMER H2 – 2006-2007 HUMMER H3 – 2005-2007 Saab 9-7X – with 4L60-E, 4L65-E or 4L70-E Automatic Transmission (RPOs M30, M32 or M70)

Problem – This relates to drivers who experience unusually harsh 1-2 shifts, along with a P0804 and/or a P1870 DTC.

Solution – It is possible that a leaking TCC solenoid, a torque converter clutch valve or damaged turbine shaft O-ring seal could cause these two diagnostic trouble codes. However, it could also be caused by a failed torque converter.

Remanufactured 4L65E Transmission Updates and Upgrades

- Used larger PR valves to ensure a full hydraulic seal for fluid

- Removed wear issues by replacing the TCC control valve, actuator feed valve, and the TCC regulator valve

- Replaced the plastic 1-2 accumulator pistons with aluminum ones to prevent early failure of the clutch

- Recalibrated the machining for stators with Tru-Flat system stator qualification and machining process.

- Replaced the old sun shell design with the most updated one to remove the most common points of failure

- Added a new 2-4 band to increase durability and upgrade the transmission’s torque.

- Replaced line bore bushing in pump to improve transmission fluid flow and improve the working lifetime of the pump

- Improved shift quality and pressure control by adding a new valve body, a complete system correction and control kit

- Improved balance past original equipment requirement by replacing torque converter

- Improved fluid control with new bushings. This also reduces vibration.

- Installed recalibration kit to update servomotors and accumulators for valves. Modifications include updates to servos, the PR system, and valve body accumulators.

- Reduced gear slipping with new kit

- Tested transmission for functionality using a road simulation program and a dynamometer. Performed tests in operational and idle states.

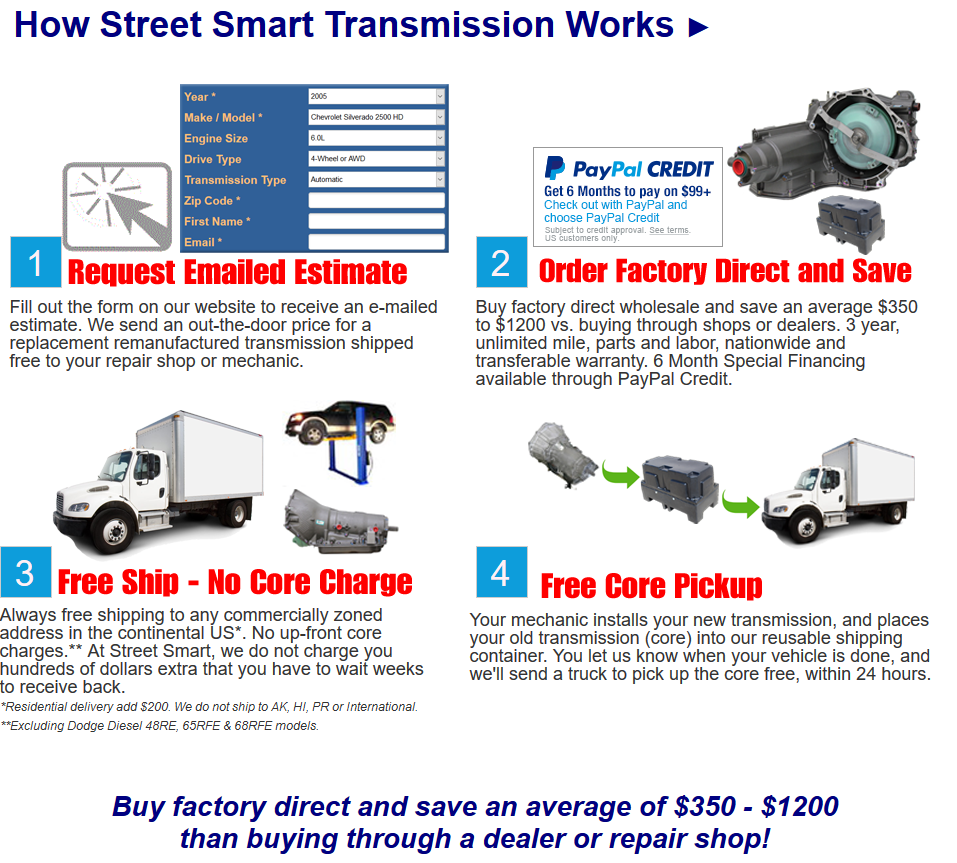

How to Buy a Remanufactured 4L65E Transmission

1) Buying Locally

When you go to your local repair shop, they’ll order a remanufactured transmission, then mark up the price. So at the end of the day, you’ll be paying 15% to 30% more than the actual cost of the unit.

2) Buying Online

Buying a reman transmission through a distributor like Street Smart Transmission will save you a considerable amount of money because you pay the wholesale price (avoiding a repair shop’s 15% to 30% markup), they’ll ship the unit to the shop of your choice free of charge, and returning your old transmission is free as well. Then all you have to pay for is the labor to install the unit (usually $400 to $800), and you’re on your way.

How Does it Work?

To order a remanufactured transmission from a company like Street Smart Transmission, all you need to do is provide your vehicle’s VIN number, the mileage, and the address of the repair shop that you want it shipped to.

Financing

Replacing a transmission can be expensive, so Street Smart Transmission offers financing through PayPal. Depending on your credit, you’ll be able to order a new transmission, get back on the road, then pay for it over time. You may have to pay labor charges for the installation up front, but you won’t have to shell out for the transmission all at once.

Shipping Charge/Location

When it comes to shipping, a transmission is quite heavy. So you’re going to pay quite a bit of money, unless the reman transmission company offers free shipping. Street Smart offers free shipping to a business address, which is usually the repair shop that you’ve chosen to install the unit.

What is a Core Charge (Core Deposit)?

Every remanufactured transmission originally came from somebody else’s car. Therefore, they need your broken transmission in order to refurbish it for another customer.

Your old/damaged transmission is called a “core”, and many companies will collect a core charge (usually $500 to $1500), which will be refunded once they receive your old transmission. However, if the transmission case, or other key components are damaged beyond repair, you may not get all of your core charge back. Make sure to ask for the core return policy, so you’ll know what to expect.

Our Recommendation

We recommend Street Smart Transmissions. We have found Street Smart to be of the highest quality. Their transmissions carry a 3 year / unlimited miles warranty that covers both parts and labor. Their warranty is nationwide and attached to the VIN so it is transferable with ownership if you decide to sell the vehicle. It also covers both parts and labor for the installation of the replacement transmission.

Watch the Remanufacturing Process

How it Works

Finding a Shop to Install the Remanufactured Transmission

If your transmission has failed, you’re going to need a skilled mechanic to replace it. You can find a shop using our shop locator map.

For warranty purposes, you need to find a reliable repair shop. That way, if the replacement transmission doesn’t work properly, the warranty will cover it.

Ready to Replace Your Transmission?

Click Get a Free Estimate for an unbeatable price on a replacement reman 4L65E transmission.

My Yukon Denali won’t shift out of first gear even if I put it in drive 3rd secound. It revs at high rpm still won’t shift. Replaced shift solenoid A & shift solenoid B. Help me

I have a 4l65e transmission

I’m driving down the highway at 65 and all of a sudden it won’t go, speed up when I press the gas

I have a 4L65e that’s shifts out fine until it gets to 3rd and about 50 mph and then it down shifts back to 2nd and you hit the acceleration and then it’ll shift back up in the third and then into fourth what’s wrong with it

DO YOU BUILD 4L65E FOR HEAVY DUTY APPLICATION?

Yes I do