While manual transmissions have remained relatively unchanged over the years, electronically controlled automatic, semi-automatic, and continuously variable transmissions (CVTs) have become increasingly complex, but also easier to use than ever before. However, modern transmissions of all types have become more prone to failure, primarily because of this higher level of complexity.

What Transmission Do I Have?

The following guide outlines the inner workings and differences between the most common types of transmissions and lists the primary advantages and disadvantages of each.

Manual Transmissions

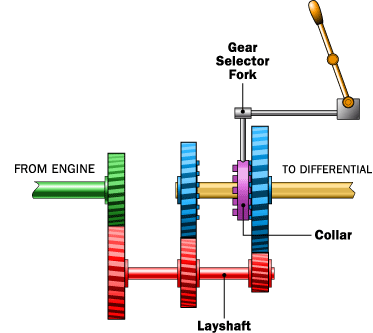

As the name suggests, the selection of gear ratios on manual transmissions is accomplished by manually shifting a gear selector mechanism that disengages one gear and selects another. Most modern types of this transmissions have five or six forward (and one reverse) gears.

This type of transmission is connected to the engine via a clutch, which if disengaged (by pressing the foot pedal or hand lever), removes torque from the system. With the clutch engaged, power is delivered to the transmission through an input shaft that is separated from the primary cluster, and which can rotate at a different speed to the cluster. The cluster is comprised of gears that can be moved to either engage, or disengage from fixed gears on the secondary shaft, which is normally located below the cluster gears, and supported by roller bearings in its casing.

Gear Selection

The input shaft has only one gear that engages with a gear on the secondary shaft. When it is running and the clutch engaged, the transmission is said to be in “Neutral”. No gears on the primary are engaged with gears on the secondary shaft.

When shifting into first gear (for example), the gear on the primary shaft is slowed down by a synchronisation mechanism, and aligned with a gear on the secondary shaft. The current gear is always disengaged before the next one is engaged. When the clutch is re-engaged, rotational energy is transferred from the transmission to the axle(s) by the drivetrain.

By using progressively smaller ratios, the speed of the vehicle can be maintained or increased using less power from the engine.

Advantages

- Extremely robust, and can handle high torque loads.

- Very reliable, and relatively easy to service, maintain, and repair.

- The solid link between driving wheels and the engine provided by this transmissions provide a valuable driving aid to drivers in the off-road environment, by allowing the use of engine braking while descending slippery slopes where the use of ABS brakes could be dangerous.

- Cheapest to repair

Disadvantages

- Learning curve – can be difficult to operate for drivers who are accustomed to automatic

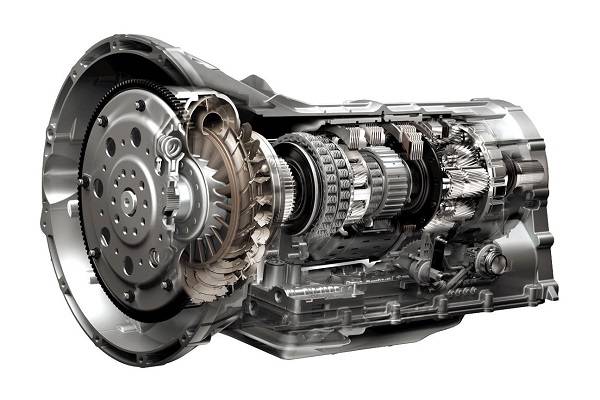

Fully Automatic Transmissions

In an automatic transmission, the hydraulically operated control systems are managed electronically by the vehicle’s computer instead of the clutch and gear stick. All the driver has to do is shift the selector from Park (P) or Neutral (N), into Drive (D), and the gear shifting will take place automatically and smoothly, without any additional input from the driver under normal driving conditions.

Gear Selection

Gear selection in automatic transmissions depends on many operational conditions, such as vehicle speed, engine speed, performance mode (where fitted) selected as well as driver assist systems such as traction control, stability control, automatic/autonomous braking and cruise control.

Provided all necessary conditions are met, and there is agreement between the Engine Management and Transmission Control systems, pressurized transmission fluid is automatically channelled to mechanisms that drive sets of planetary gears and clutches, which are roughly analogous to the gear ratios found in in this type of transmission.

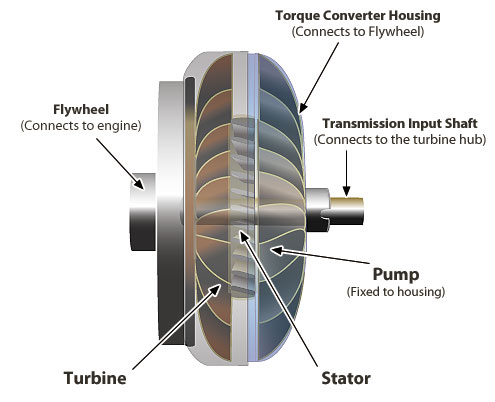

Rotational energy is provided by a torque converter, a mechanism consisting of two freely rotating parts. One half is attached to the engine and the other to the transmission input shaft. The two halves of the converter are positioned very closely together. The fluid that circulates between them is influenced by the rotational energy of the engine which in turn impacts the transmission side of the converter. Torque is transferred from the engine to the transmission thanks to the shearing strength of fluid.

In older automatic transmissions, the shifting action was accomplished by internal fluid pressures overcoming spring tension – closing one circuit before opening another. This control system produced harsh, jerky shifting. Modern systems moderate the action of the controlling valve shuttles, providing almost seamless shifting.

Advantages

- Very easy to use

- Provides a comfortable driving experience

- Modern automatic transmissions match manual transmissions in terms of performance and fuel economy

Disadvantages

- Complex and prone to failures, malfunctions, and unsatisfactory performance due to a variety of possible issues, some of which are unrelated to it itself

- More expensive than a manual transmission to maintain over a vehicle’s lifetime

- Expensive to repair. Replacement is often the more cost effective option

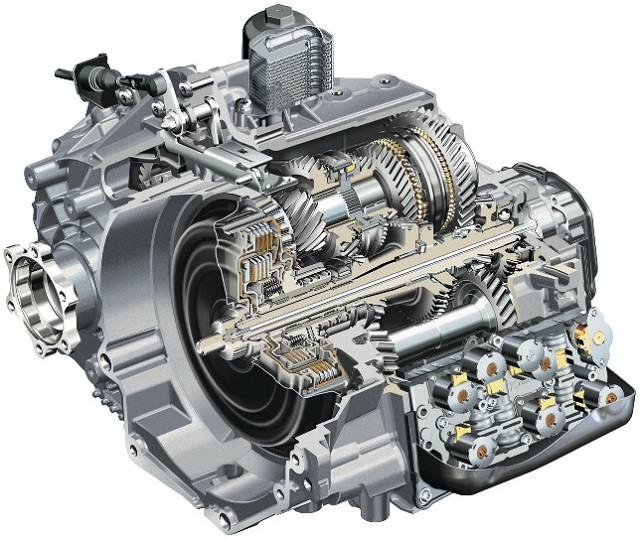

Semi-Automatic Transmissions

Also known as an “automatic manual” or “clutchless manual” transmission, the simplest way to describe this type is to call it a hybrid between a fully automatic and manual transmission.

Similar to a manual transmission, gears are changed via a simple shifter or paddles located behind the steering wheel. However, there is no need to operate a clutch pedal. Processors, sensors, pneumatics and actuators are all used to “automatically” shift the gears once the drive has signalled the change.

The basic principles of shifting mechanical gears in a semi-automatic fashion have been in use on heavy commercial vehicles for many years. The latest and best designs provide lightning-fast, almost undetectable gearshifts.

The design of these systems varies, but all semi-automatic transmissions rely on microprocessors to control the changing of mechanical gear ratios with the help of electrically operated actuators and servos. These transmissions were limited to high-end supercars at first due to their high cost, but an increasing number of manufacturers are fitting them to mid-range cars.

Dual clutch systems employ two clutches, one controlling gearshifts in the even numbered gears and, anther that controls the odd numbered gears and reverse. This arrangement does not interrupt the power flow from the engine. The driver still has to initiate a gearshift via a shifter or paddles located behind the steering wheel, but there is no need for the driver to operate a clutch.

Advantages

- Smoother shifting/driving experience

- No energy losses due to slippage in torque converters, or during the time lag of manual shifts

Disadvantages

- Complex and prone to failures, malfunctions, and unsatisfactory performance due to a variety of possible issues, some of which are unrelated to the transmission itself

- More expensive to maintain than a manual transmission

- Very expensive to repair. Replacement is often the more cost effective option

Continuously Variable Transmissions (CVT)

Unlike the others on this page, this transmission doesn’t use gears as its means of producing various vehicle speeds at different engine speeds. Instead of gears, the system relies on a rubber or metal belt running over pulleys that can vary their effective diameters. To keep the belt at its optimum tension, one pulley will increase its effective diameter, while the other decreases its effective diameter by exactly the same amount. This action is exactly analogous to the effect produced when gears of different diameters are engaged.

“Gear” Selection

Since one pulley is driven by the engine and the other is connected to the drive shaft, an infinite number of ratios can be produced. This enables it to always run at the most efficient speed, regardless of the load placed on it. Microprocessor-controlled sensors quantify load variations and by adjusting both pulleys, the optimum operating speed for the engine can be maintained without any input from the driver.

Advantages

- Constant, stepless acceleration throughout the engine’s optimum operating range

- Provides a comfortable ride by eliminating “shift shock”

- Better fuel efficiency

- Faster response to changing driving conditions such as variations in throttle and engine speed

- Eliminates energy losses associated with torque converters. Bottom of Form

Disadvantages

- Unsuitable for use in off-road environments because of limited torque-handling ability.

- Cannot provide engine braking

If you have a question, let us know in the comments and we’ll do our best to help you out.

What Transmission Do I Have?

I need to identify my transmission to get the proper torque converter

Broken shifter metal filings in pan. I bought the bronco this way.

I have a 2018 ford f250 4wd with a 6.2 gas motor and when I’m driving it sounds like the torque converter is engaging and disengaging every 30 sec or so and when it does this I hear a rattling noise like pebbles in a coffee can . No slipping no hard shifts not running hot Trans works as it should other than this engaging and disengage and the rattling sounds just like a heat shield is loose that’s the sound it makes anybody else have this same truck and have this problem . Mind you this has been going on for over a year and I pull trailer everyday 10k + pounds every day across the country and I bought this truck new in 18 I’m the only owner and it’s pulled trailers its whole life from lawn trailers every day to my 20ft enclosed and my 40ft flat bed gooseneck. Can yall give me some input on this before I take to the shop that’s going try and get me for thousands of dollars cause before that I’ll trade it in quick !! FYI TRUCK HAS 136K MILES ON IT

Hero driving reverse but it won’t go forward and out of my forward deals

The transmission 4r-100 attempts to upshift and downshift at the wrong time. The result is high rpm & not shifting or low rpm and no power. Freeway driving is very slow. Reverse sometimes doesn’t work. Time to replace? What is an available alternative transmission?

4r-100 for a 2000 National Sea Breeze RV. Has Ford v10.

Was also wondering If you offered a better replacement for this transmission that will work on this engine and my RV?

Shifts but stalls out

There’s a popping noise when it shifts gears

Hi, my name is Steve and my sister has a Nissan 2005 pathfinder with four-wheel-drive she’s having problems with her transmission we think, some say it’s a clutch brake problem in the tranny because maybe they don’t know. It has a tendency to vibrate at higher speeds. At lower speeds I don’t notice anything, some say it’s in the you joint system or brakes tires supposedly the experts say break stop whatever that is. Does anyone know what or how to figure out what his problem is?

I just did down below I’m craig dolbec can you help me with my issue with my truck ?

We’ll as I was driving on a repaved road doing bout 65 -70 mph a left turn I supposed to make I passed by so I suddenly slammed on the brakes w/ out going into a skid ! Of course everything in the cab went flying forward ! So then I reversed and took my left turn and jumped on the gas peddle with a Vengeance and the engine and trans got busy and the RPM gage almost “Red lined !” So I let off the gas and then the trans shifted to 2nd . And then third and of course 4 th !!! The engine light came in blinking like crazy so I pulled over and assessed the problem but nothing was apparent so I jumped back in and took off knowing I had another 30 to 50 miles to go before I made it home ! So w/ the engine light on I made it home but I couldn’t raise the R’s up too high or it won’t shift , but mostly when the passing gear drop was called for it wouldn’t shift. Ok the next day I get my reader out and get busy looking up codes . The first code that read was PO300 which we all know it’s a “misfire” code which lead into a mass air flow sensor, I bought a new MAF sensor and installed it and sure the truck fired right and the engine light went out ! Took off for a good drive , to check things out and my test drive ended very quickly, I get 1 st, then second and the minute I’d step on the peddle the RPM’s would race to the sky and the truck wouldn’t go any where and engine would stumble and almost die. Figure this one out and I’ll buy you a dinner – I don’t know if it’s the trans , throdlebody, speed control valve or god know best but I don’t want to have to buy a replacement trans or not – rebuild this one (I don’t trust anyone in rebuilding my trans – I just don’t) so I’d go with a low mileage trans out of salvaged truck and take my best shot with that Help me with this issue I’m at a standstill can’t figure out what to do next and I need my truck for work !

Need to know the Ratio of my 2003 Buick LaSabre Transmission