Forum Replies Created

-

AuthorPosts

-

HostgatorMember

There are a couple things that make your van behave as it is behaving. In no particular order, it may be the torque converter is slipping a bit (doubtful, but possible). It could be the turbine slipping a bit (again doubtful, but possible). It may be the clutches that are slipping a bit (more likely, but again possible). Combined with the clutches, it could be the bands that are slipping (again more likely). It is possible that it could be the planetary gears themselves that are slipping a bit because there may be worn spots or a cog may be out of possible because it is slightly bent or nicked. It could also be that a solenoid pack is failing, but hasn’t quite gone yet.

You can see the many different possibilities that could be troubling your Venture. They are nice vans — I sold them for a bit so I am familiar with them — but like every other vehicle they do require maintenance.

You told me in your question that you have had all of the major service recommendations completed to which I say great. You are way ahed of lots of vehicle owners on that score, but, you told me something else that tripped an alarm in my mind — you haven’t changed the transmission fluid in some time.

Yes, I know that I could walk out to my sedan right now, pull the dipstick, rub the transmission fluid across my finger to see if it felt grittle and sniff it to see if it smelled burned. I don’t think that it would be, but, who knows? I could see if the levels looked right, as well. I also know they are probably right, as well.

With all of that said, though, you told me everything looks okay, but I have to tell you that it isn’t, if you haven’t replaced the transmission fluid in a while. Yes, the fluid has to be swapped out on the intervals outlined in your owner’s manual. If not, it starts to break down over time and begins to cause problems.

That’s exactly what I think is going on now. You see, premium transmission fluilds are vegetable-based, not solely petro-based. Because they are organic, the heat that they continually carry off begins to break them down over time. As they break down, their heat-carrying capacity falls, as well, as does their ability to protect the transmission.

The funny thing about the start of the breakdown is that if you pull the dipstick and look at the color of the fluid and sniff it, you won’t suspect anything is wrong because, at this point, it looks quite normal. But, trust me, it isn’t in good shape, if you have let it go beyond its safe point between 30,000 and 40,000 miles.

Here’s my suggestion: get the van to a good independent shop; have the transmission fluid drained out, not forgetting the quart or so in the pan (yes the lid has to be opened), closing things up and putting in a clean refill. I think this should fix the Venture right up. (While it’s open, if you have access to the transmission filter, I’d swap that as well.)

Need a replacement transmission? Quality transmissions are hard to find. Free estimate to your email.HostgatorMemberShort of the gas can solution — and I know you hate to hear this — but I would consider installing a rebuilt transmission. There are so many things going on in your transmission that I don’t know where to begin, so I’ll start with a biggie: the heater warning.

I’m not sure if you know this — you probably do and I’m repeating myself — but the transmission generates massive amounts of heat. It is just as bad as the engine. Now, here’s the thing about the tranny, unless you have a separate transmission cooler installed — they make them — then your transmission and engine are sharing the same cooling system.

Most of the time this is just dandy for both as there is enough capacity for proper heat extraction from the engine and transmission. And, if things are getting too toasty under the hood, the fan comes on electronically.

For the tranny heat to get into the engine heating/cooling system, there is a separate set of heating/cooling hoses that take care of the transmission’s business. In the usual order of all automotive things, those hoses wear just like the ones on the engine. The only problem with this is that most people don’t think about these hoses and their hardware. They can become mushy or brittle and can collapse on the inside, though they look okay on the outside. And, they can wear at the clamps that keep them attached — a common point of failure.

Are you still with me? Here’s the importance of the transmission hoses, if the transmission can’t shed heat properly, the heat has to go somewhere, and it goes, of course, into the transmission itself. Since the tranny isn’t set up to handle to extra heat, components can fail. Things like the shaft bushings can become soft and deform. And, there is a host of internal bushings that can also deform, causing damage to the delicate parts of the transmission (clutches, bands, gearing which can be thrown out of proper orbital alignment and the like). That’s why your Lincoln’s warning lights are screaming at you.

And, from what I have read in your question, things have gone a long way, the wrong way. And, I realize the $3,400 to $4,000 (depending on your location) is a huge hit on a limited budget (I know, we live on one ourselves) but if you plan on keeping the Lincoln, you will have to bite the bullet and do the fix.

Honestly, if you try to piecemeal the repairs by doing the solenoids and then maybe the clutches and bands and then maybe the torque converter, you will find the cost is far more than just investing in the rebuilt. It does seem cheaper if you do them one at a time but trust me by the time you have finished — and who knows if they will work because there’s always something that’s missed in a piecemeal repair — you will have spent a lot more than the transmission costs.

As for the Lincoln, I wouldn’t take the gas can approach. Who knows, you probably need the transportation and if you own it to the ground, then putting in a new tranny and getting a few more years, is worth it!

HostgatorMemberI don’t think it’s the solenoid for the following reason: when an electronic part like a solenoid breaks it usually happens all at once. If that were the case, then you wouldn’t be able to make the shift at all either getting into the gear or getting out of it.

I know this sounds like a cop-out, but I have to ask you how long has it been since your last transmission fluid check? If the fluid is down a quart of so then parts of your transmission, such as the torque converter or planetary gear chain may be high and dry, relying on brief spurts of high-pressure coverage from the transmission (transmissions do operate under pressure and at times can build extra pressure within the case as they try to make up for fluid that is not there). It’s not a good idea to let this last very long.

I would get the car into a good independent transmission shop and have the current fill of transmission fluid drained and refilled. While the transmission fluid is drained, I would also have the transmission filter swapped out and replaced to keep things working smoothly. Be sure to have the technician drop the transmission fluid pan cover to empty the last half-a-quart or so that always remains within the case. Then, after putting the cover back on with the proper gasketing, of course, the tech should replace the fluid with the proper fluid for your transmission. You will find that listed in the owner’s manual. Never let the transmission be overfilled because there will be too much pressure within the tranny and nasty things can happen.

Let me know what happens, I’d like to hear the results.

HostgatorMemberOkay, I think I know the answer to this but I have to ask: when was the last time the transmission fluid changed? If it has been some time, then it is possible that some debris has broken loose from an impeller turbine, for example, and has floated downstream to where it is blocking a key gallery or channel and it is keeping reverse from engaging.

The way this happens is that the debris floats along until it gets to the valve body. The valve body is a device that is full of galleries and check valves at their ends. When you choose a gear, the gearshift solenoids fire in a specific order to determine the correct gearing. Everything seems to be find in this area as your A6 is trying to reverse, however, it is essentially failing. By essentially failing, it is going into gear but not moving very much.

That indicates to me that everything in the transmission is working correctly to that point. However, since there is a constriction in the fluid flow through the valve body to reverse, the gear is not receiving the correct flow of transmission fluid and it is, as a result, working poorly or not at all.

This is a fairly straightforward fix. Of course, the transmission has to be dropped from the housing and disassembled so you can access the valve body which sits on the outside of the transmission but is not easily accessible without a partial disassemble. Once the valve body — a device with lots of channels and galleries that direct the fluid to the proper gear — is exposed you will probably see one or more channels/galleries with gunk in them, usually at the check valve so that instead of the valve opening and closing in response to demand, the check valve remains partially closed most of the time, only allowing a little fluid through at a time, causing your problem (a check valve consists of a lightweight ball-bearing and a light spring that closes and opens in response to the demands of the transmission’s gearing).

Your technician will run the affected galleries with a device that is like a pipe cleaner and will clear out the gunk and other debris and will also replace the checkvalve and spring, repeating this process until all the dirty channels are cleaned (a gear may have more than one gallery devoted to it). Once they are all cleaned and the valving is working again, the technician will button things up and refill the transmission with the proper fluid to the proper levels.

That should do it.

HostgatorMemberMy thinking on this is that if you are replacing everything in an electronic chain, then you have to replace all of the components at the same time. It doesn’t do much good if you replace four or five items and leave the sixth only to have the sixth fail when you put everything back together.

I would also suggest, if you can, swapping out the TCM (tranmission control module) and any related sensors such as the MAF (Manifold Air Flow) and the MAP (Manifold Air Pressure) plus the TPS (Throttle Position Sensor) and the shaft speed and wheel speed sensors. The reason is that your Cavalier has 160,000 miles on it and it is more than 16 years old, not exactly new. Each of the sensors has lots of miles on them and they will likely be points of fialure sooner rather than later, especially if you swap out other sensors and the TCM.

Once you have everything installed and the tranny is buttoned up let me know how things are going.

August 23, 2017 at 10:55 am in reply to: 2004 Grand Prix won't shift out of first unless uphill #9926HostgatorMemberIf the 1-2 shift solenoid has gone bad there’s nothing you can do but replace it. Of course, if you want to keep on using it, your Grand Prix will continue to act up and still won’t shift. Eventually, since both the solenoids were installed at the factory, at the same time, the 3-4 shift solenoid will also fail and you will be let with an engine that starts up nicely, but the transmission won’t work at all.

I realize that the 1-2 solenoid may be the one that is inside the valve body so the transmission will have to be partially taken apart to get to the failed part, but, it is the best idea to fix the solenoid since it is very possible — I am not saying it will happen, just that it is possible — you will damage the transmission by relying on third starts and fourth/fifth cruising. Is your tranny shifting into overdrive — fifth?

That’s my take. It should cost about $800 for labor and parts.

HostgatorMemberI think you have pretty much outlined what you have to do. I don’t think the hard shifts have damaged anything permanently. Your transmission is made to put up with a certain amount of daily wear and tear and hard use and hard-shifting falls within that description so I don’t think you need invest in a rebuilt.

I do think, though, that from the sound of the symptoms that swapping out the solenoid packs is warranted and if you can get easy access to them, I’d say go for it. Since you have already fixed the major problem (the sensor), fixing the secondary ones is now in order.

Once you’ve done this, I believe you’ll find the transmission works quite well. And, you have saved yourself more than $2,500 because you didn’t have to put in a rebuilt.

HostgatorMemberYou could try draining and refilling the transmission properly (never use a high-pressure drain) and replacing the filter and transmission fluid with the proper type (it’s in the owner’s manual). And, it may work for a time, emphasizing MAY WORK, because I think there’s a lot more going on than just the fluid.

You told me you were driving along; hit the brakes, while reversing. Well, I have to tell you that this isn’t very good for any extended life for your transmission. Indeed, it’s probably the worst thing you can do.

Here’s an example of what has happened. Imagine you are running along in, say a marathon or half-marathon. As you are running, someone falls in front of you so you have to stop short and you have to jump backward. Did you feel the pop in your knees? If so, you may find that you have suddenly become a casualty as well because you have just torn the ACL or MCL. Effectively, you have done the same thing to your tranny.

At best, you may have just hyper-extended the bands/clutches and gears or you may have popped the torque converter. However you choose to put it, I think there has been a bunch of internal damage which has turned your transmission into “junk,” to quote your question.

If you want to hold onto the pickup, my advice is swapping out the transmission and putting in a rebuilt for starters, which should cost about $3,400.

Here’s where it gets a bit dicey, though. Because of the way things happened, you may have damaged the input and output shafts and you may also have damaged the differential, as well. If that’s the case, then you are looking at another $2,800 in repair expenses which will push things over the $6,000 mark.

Let me know what happens, I would like to know.

HostgatorMemberThe 06 Cobalt, like most GM cars, uses two shift solenoids on the outside and inside the valve body. The way they line up electrically causes your car to shift.

Since you have lost fifth gear — the Cobalt of that era used a five-speed automatic — it is most likely solenoid two that has failed. At that it is likely only one side of the solenoid that has failed as you have gears 1-4.

Fifth gear is actually an overdrive type of gear that lengthens the gearing so your engine turns more slowly for the speed. It is one of the ways your Cobalt gets the reasonable mileage that made it popular.

I would suggest a couple of things to make sure your 12-year-old car remains in good shape — at least for transmission health. The first is taking it to a dealer (Chevy) and having one of the techs there run a full OBD-II diagnostic. This should reveal if there are any other problem areas that are going (Today’s OBD-II diagnostic is pretty comprehensive and while the scanner generally points at overall areas where problems may occur, the software has been refined to the point that you should find out where other problems may lie. It will also show you which solenoid pack has failed.).

Second, Id have the transmission drained and refilled to ensure it operates properly. Some shops use a high-pressure style transmission drain that I don’t advocate. The reason is that the high pressure jet may dislodge crusted deposits that could remain within the transmission, causing further damage later on. The proper way to drain the transmission is the remove the drain screw/plug and draining it into an environmentally friendly container (one made for this purpose). This will leave about a quart or so within the transmission pan. To remove this last quart there are 14 or so nuts that have to be backed out so the cover comes off. Be sure you have a bucket underneath to catch the fluid. Also, take a look at the drain plug as it is somewhat magnetic, to see if there are any metal shavings or shards that could indicate internal damage. with everything drained, replace the cover, being sure that you are using the right gasketing material (some use a fiber-style gasket, while others use a variant on RTV (room-temperature vulcanizing agent)), and replacing the nuts. Don’t overtorque them because you risk warping the cover. Hand-tight and a quarter-turn or so is all you need. While the transmission is open, replace the filter that you will also find in the sump. Refill with the recommended transmission fluid (it is in the owner’s manual), using the right number of quarts. You refill through the filler neck.

Let me know what happens.

HostgatorMemberCould you clear up something from me, was the Avalon towed with the front end lifted and running on the rear wheels or was the rear end lifted and was it towed with the front wheels down? Also, was the transmission left in gear when you did the tow? Please let me know as it could make all the difference in the world.

And to give you a quick answer, it does sound like limp-home mode.

Let me know the details if you could as it will help me get the right information.

HostgatorMemberFrom what it sounds like, I have to say this, though you have done a ton of work, it sounds like you have missed a step.

Here’s what I would suggest: start from the beginning (I know this will take some work) and then work through each section of the transmission to ensure that it is hooked in correctly. All it takes is something relatively small, like a clip inserted backwards and the transmission acts just like you have said it is acting.

I honestly suspect that as you go through things that you will find that you have turned a spring or springclips around so that while they look like they are installed correctly, they are really backwards so that the clutch plate and pressure plate, for example, are not exerting pressure and completing the mechanical linkage you need to make things work.

Indeed, I think you will find that you may have even inserted the clutch plate or pressure plate incorrectly so that instead of pushing forward when you release the clutch, they are come apart. I realize that mechanics have told you everything looks okay, but, since your Mondeo isn’t moving, then something’s obviously wrong.

In your checking, I would pay special attention to the clutch springs and the pressure plate springs to ensure they are working correctly. Likewise, I would check the throwout bearing closely. Though it can honestly be inserted in one direction, you may find that you have inserted it incorrectly so that the device that is key to proper clutch operation — the throwout bearing — is inserted so that it is working incorrectly. Or, if the device is inserted correctly, it is possible that the springs that are suppose to help it engage correctly and disengage correctly have either been swapped or they are turned around.

I hope this helps. Let me know what happens.

August 3, 2017 at 2:43 am in reply to: Stalling, Whirring and Clicking – Torque Converter or Solenoid? #9894HostgatorMemberI would advise you to hold off on dropping in a rebuilt transmission until you have tried something. Have the transmission specialist look closely at the clutches/bands. You see, if the clutches don’t engage smoothly — or at all — your car won’t move. The Corolla will start and just sit there with the engine spinning away. The same is true of the clutches partner in transmission operation, the bands. The bands operate by tightening the linkages between the engine and transmission so the transmission operates as efficiently as possible.

The clutches/bands also make sure that the transmission shifts smoothly from gear to gear.

Please note that if there is a problem with the the transmission parts then an error code will be generated that can be read with the OBD-II software and diagnostic tool. So, you can be sure that this isn’t the primary culprit and cause of your problem. Indeed, I suspect the problem with your Corolla involves mechanical systems, rather than transmission-related systems.

Given that I would look closely at the sensors that are located on or at the wheels or on or at the or the sensors that are on or at the half-shafts that. The failure of these sensors will render the vehicle undriveable.

HostgatorMemberLet me ease your mind with one statement, your transmission has a problem or problems but doesn’t require the $2,000 investment in time and money you will need to replace your Hyundai’s manual transmission.

Let’s get to your specific issue, though. From the sound of it the problem area is the clutch/throw-out bearing/pressure plate and related parts. The reason I say it is because I am just repeating the information you gave me. However, to take this a bit further, when you press the clutch in, the throw-out bearing is activated and it pulls the clutch plate clear of the flywheel on the engine.

In all of this, the throw-out bearing is an actor with a limited role. It simple is activated by the clutch pedal and it causes the clutch plate to, as noted, separate from the engine. When you release the clutch pedal, the throw-out bearing relaxes and there is a hard connection between the engine and transmission.

I suspect the throw-out bearing is the culprit here. There are times when the bearing becomes lazy and sloppy causing shifting to become sloppy, though you don’t see this directly. Instead you receive noises like rocks being crushed or whining.

I’d have the throw-out bearing replaced asap to end the immediate problem. I would also have the clutch plate facing changed as it might also be slipping, causing the transmission to whine or grind.

Changing the throw-out bearing is roughly a $420 repair while the clutch plate facing costs about the same. If it still grinds after these repairs, have your tech look at the specific gears as there might be a problem there or it could be a synchronizer is failing.

Let me know what happen, will you?

HostgatorMemberHey, thanks for the kind words. I always enjoy hearing from you guys and I have tried to help readers out for a very long time. I remember one GM products that … well, I can’t really go into it but suffice to say it was a positive result.

With that said, I think you’ve done a great job of troubleshooting the issue and I think you have hit the nail squarely on the head. From the sound of your issue, your transmission is working — you have to use manual shifting, but it goes into the gear you select and moves along in that gear quite nicely.

Now, it is true that there are a number of conditions that could mimic the problems you have outlined, but, here’s the thing of it, they would generate a code and it would be captured by the Engine Control Module (ECM). And, since you are not getting any codes generated, I believe that the problem is purely mechanical and outside the transmission.

It is also possible that the tire/wheels have a problem. If one of the corners of the SUV breaks then essentially you are asking three wheels to do the work of four. Now if this were possible, your vehicle would just pivot around the bad wheel in a big circle. So, if you have a combination of VSS failure and the failure of a tire/wheel on one of the corners, then you have a condition that could easily cause your vehicle to surge.

Hold on, though, this brings up another group of possible causes, electronic. Though you have touched on it fairly well in your question, I will expand on it to say that if one of the wheel sensors or a sensor on the crankshaft has gone or is sending back faulty information to the ECM — also the chief computer in the engine bay — it is easily possible that the combination of the bad sensor and the ECM misreading the information, is causing your SUVs transmission slipping. The reason there is no code being generated is simply that the ECM isn’t reading it as an error so there’s nothing reported or stored.

Let me know what happens.

You asked me two specific questions and I have to tell you that if your VSS (Vehicle Stability System) is gone or going your vehicle will act much in the manner you describe — surging and the like as the VSS tries to right things, causing the crankshaft to turn at unacceptable rates.

HostgatorMemberHere’s one, why on earth would you listen to a tech who tells you he’d get you a transmission the only trouble is that it is generating five error codes instead of just one. And, the one that is being raised by the diagnostic scanner — 46 — points to one of the solenoids which is a fairly quick and inexpensive (for the transmission). The shift solenoids are located either on the valve body or inside of it. Yes, getting to those inside does require a teardown of the transmission before you can insert a new solenoid. However, I think that when you look at the $700 or so bill you would receive to replace the solenoid versus the $3,400 bill you would receive to replace your current transmission with a rebuilt that it makes far more sense to invest in fixing the first transmission.

That’s my thinking anyway.

By the way, I would honestly be wary of a supposed tranny expert who finds you a transmission with more problems than your original had and then having the same expert telling you to find a rebuilt to fix the problem.

Please note that BMW service rates are among the highest in the business so be sure you can find out if your local dealership can do the work at an agreeable and affordable price.

HostgatorMemberIt’s quite possible that your Honda’s surging is related to the transmission, however, I think there are other parts to check out first.

For example, if he engine control module is sending faulting information to the powertrain and its sensors, then, it is very possible that your Accord will surge. And, honestly, I think you or your technician should be running down each electronic element in the ignition system.

For instance, if the BARO (barometric sensor) is receiving faulting information from the MAP (manifold air pressure) or from the throttle positioning sensor (TPS) or a combination of these sensors, then your Accord will very certainly act as you describe it.

Though the 94 Accord was highly electronic, it is nowhere near as electronic as Accords are today. Still, even the more rudimentary electronic devices on your drivetrain, wheels and transmission, if they have failed or are failing, will guarantee that your engine surges and hesitates.

Here’s my thinking on what your next steps should be:

- If you are doing the work yourself, then, find a OBD-II scanner with the proper software and check to see what it finds for error codes.

- Take the error code readout and find the areas it is pointing to. Remember that today’s cars, as I noted, are far electronic than cars were 23 years ago, and the error codes will pinpoint a problem pretty precisely. However, you should still get the general area where the problem is occurring.

- Find the service manual for your car and then look at the problem areas that are shown so that you can find the parts you need.

- Swap out and replace the parts, if you feel you are qualified.

- If you don’t feel qualified, take your Accord to a service area that handles them and have it repaired.

Normally, I am happy to price out and estimate what a transmission repair will cost you, however, since I think the problem is more mechanical than transmission, I will step back and let your technician answer that question.

One though before I close and that is don’t forget your electronic check should include the transmission control module (TCM) and the sensors that are related to it. It is possible that the TCM has gone intermittent (it fails and then works correctly and then fails again, but there’s no rhythm to it) or that one or two of the sensors that show up on the ECM report, while they also report their codes to the TCM may also have gone intermittent or have failed. Let me know what happens. I honestly do want to find out.

HostgatorMemberThanks for all the input. I can tell you this much from the top that your Accord needs three new sensors, the BARO (barometric) the CKP (Crankshaft Position Sensor) and the HO2 sensor (Heated Oxygen sensor). As I looked at the information I have on Honda error codes, it also struck me that with each sensor description there was the cryptic ECM or Engine Control Module. The ECM is the big kahuna of engine modules, it is the microcomputer that provides the software to each sensor or module in the engine and it also takes the information, puts it all together and then makes decisions about emissions setting, accelerator settings (we haven’t honestly had accelerator control for nearly 30 years, it has all been done by computer). The other three sensors report to the ECM. All of them deal with emissions and fuel economy.

From what you have told me it could be that one or more of the sensors has gone intermittent and could be shorting out the ECM, causing your transmission problems. I think the primary candidate in this one is the CKP as it sits in that chain of engine software, the one dealing directly with the engine and transmission — the powertrain. If this sensor is gone, then it is quite possible your Accord is acting the way it is acting. I’d suggest swapping out the three sensors I mentioned and the engine control module. I believe that if you do most of the problems you have discussed with me will go away.

One other area to check — you have already started with the first solenoid — is the solenoid packs. There are two in your Accord, one should be on the outside of the valve body and the other should be on the inside. I don’t know which one could be going or gone, but I have to suspect it could be either. I’d suggest replacing both and that should pretty much fix your Accord’s problems.

All told — between the sensors, engine control module and solenoids — you are looking at an investment of about $1,500 for parts and labor. If you think that it’s worth it in a vehicle that is, after all, 23 years old, then I would say go for it. If not, then why not turn the old Accord in on a slightly newer model. One of my closest friends just put the third transmission in his 2002 Accord EX 2.2 that has close to 350,000 miles on the odometer. He’s happy with the decision he made and his Accord seems quite happy, too.

HostgatorMemberGlad I could be of service!

HostgatorMemberI’d love to be able to tell you to storm into the office, receipts in hand, and demand that the seals be replaced under an implied warranty, however, three years is pushing it. Granted, you would think that axle seals should last longer than three years, however, if you look at the basic consumer laws where you are, you will likely find that major repairs are warrantied for a year. After that time, you are pretty much on your own.

You might try this tactic to see if you can get some traction on your claim. Suggest to the technician or the manager that since the seals failed under four years that there might be something wrong somewhere and that it might be a good idea sit down to see if there might be some accommodation available, say, half-cost, split between you and the shop. Or, you might suggest some other plan where you pay a bit, but the shop pays more.

Honestly, I don’t know if they will bite because three years is still three years and seals do fail in 36 months. The shop is well within its rights say no and charge you full price.

July 11, 2017 at 2:41 am in reply to: Newly rebuilt 2008 nissan altima transmission with problems #9841HostgatorMemberMarch — better drive — the Altima back to the shop and have them look for a transmission fluid leak. You shouldn’t be having the problems you are having and the only way they can be happening is if there a drop in the transmission fluid level.

How could a drop in the transmission fluid have occurred in three weeks? There’s really only one or two ways. When the shop buttoned up the case on the rebuilt they forgot to run a bead of gasketing material along the transmission pan cover when they put it back on. The result is that there is a micro-leak occurring and the fluid level is dropping.

Alternatively, they may have cross-threaded the transmission fluid drain plug when they pug it back in and there is a very fine leak of fluid running down the misaligned thread. I’d suggest looking under the Altima for a red fluid stain or puddle which would indicate there is a leakage problem.

Another area to look at is the transmission radiator hoses — the ones cirulating anti-freeze/coolant around the tranny in the water jacket and taking the heat away from the already-hot unit (the transmission is one of the biggest heat-generators on your Altima). Be sure the hose clamps are snugged up correctly and that the hoses aren’t cut or otherwise degraded.

If everything looks okay here, I’d suggest there might be a misaligned input or output shaft or one of the half-shafts is out of alignment. Each case can result in leaks in your recently repaired Nissan.

Since the repair was done a few weeks ago, the shop should have already warrantied the work so you won’t have to lay out any money. I hope this helps. Let me know.

July 9, 2017 at 2:46 am in reply to: Toyota Prado 26/62 Code Only Moves in Drive With High RPM #9839HostgatorMemberWhen you receive the 26/62 combination, it indicates there is a problem with the shift solenoids for starters.

In the Prado, there are three shift solenoids that must be replaced. You will have to drain the transmission so that you can locate them. One of the shift solenoids is located on the tranmission’s valve body while the other two should be located on the inside. Because of the interior location, you needed to drain the tranny.

I’d suggest, at this point, obtaining the service manual for your Prado’s automatic transmission because you will be able to identify the spot each solenoid resides in.

The 26/62 error code also could mean there’s a problem with the valve body for which you will need to inspect the valve body closely. You are in luck, though, because you already have it open to replace the solenoids.

The same error combination could indicate there may be a problem with the torque converter. Since the converter is central to the transmission’s proper operation, I think you should be thinking of installing a rebuilt transmission. I know you don’t want to hear this, but, you’ll save yourself a lot of trouble, many piles of headaches and, in the long run, your transmission will work correctly pretty much from the get=go. The work, brace yourself, will cost about $4,000.

HostgatorMemberBefore you go worrying about replacing the transmission at this point, I want to asked you, did you look at all of the gearing? Since about the late 1980s, most U.S. SUV equipped with manual transmissions also used synchronizers. Though most people don’t think this is true, it is, believe me. The synchros allow you to upshift and downshift without worrying about matching engine/transmission speeds manually so the gears won’t clash.

Think of synchros as something like a specialized clutch for each gear. Working automatically, the synchros allow you to shift smoothly and quickly and without much thought.

The synchros are my first suggestion. Next, I’d suggest having the transmission rails for third and fourth looked at. This should work so that when you shift into third, the gears lineup correctly and likewise with fourth. If the rails won’t match up then it is unlikely your transmission will shift as well.

Then, of course, there’s the shift pawl itself. Is it lining up correctly so that your Ford is going into the correct gear? How about the gearshift line? Is it binding in the carrier?

You started out your diagnosis work quite well, however, there is still more to go.

HostgatorMemberThis may sound like a rather basic suggestion — it is, I know — but try looking at the solenoid packs again. Are you sure that you have the proper replacement solenoid? If you are certain the replacements are proper, have you installed them in the correct positions? It is very easy to slip a solenoid pack into what you think is the right spot only to find out later that the solenoid is the wrong device.

I’d suggest that you pull out the solenoid packs and then make sure that the 1-2 pack goes into the right carrier and the 3-4 pack goes into the right carrier.

I’d also suggest making sure that the electrical connectors are properly inserted. It is easy to turn things around so that the plug is actually wired in backwardly. In this case, even though the resistance may look as if it is correct, it is entirely possible that because the connector could be backwards. There are some connectors in vehicles that can easily be placed in so things are backward.

Let me now what happens if and when you check things and change things around.

HostgatorMemberAfter your experience, I can’t say I blame you one bit, however, I think the technician was onto something. The problem is he didn’t take it far enough. Whether you realize it or not, the transmission is one of the biggest heat-producers in your van’s engine bay. And, since the Odyssey is a front-drive minivan, with everything combined into a transmission/axle or transaxle, many of the driveline’s parts that are spread out in rear-drive vehicles are crunched together, creating even more heat.

It sounds to me that the technicians who worked on the minivan put a special heavy-duty add-on radiator kit into your van. However, I also think that the job may have been a bit much for him to take one. No, I am not saying he couldn’t do it or didn’t have the knowledge needed — not at all. What I am saying is that the technician may not be totally familiar with the ins and outs of transmission coolers and the lines used to take the heat away.

And, here’s where I think things went sideways. When the tech put in the cooler kit, it seems to me that one or more of the cooling lines from the minivan’s anti-freeze/cooler system may either have been installed incorrectly or may have pinched so that there is little if any transmission fluid zipping through the add-on cooler kit.

Usually, when an add-on kit is installed, it goes to great lengths in telling you where to bolt it; how to prepare the existing hoses (a lot of transmission heat is taken out of your minivan’s transmission by the cooling system); what to clean, and what to look for.

If one of the lines pinches or if it is installed incorrectly so that any thermostatic control device may be upside-down, then there’s no fluid going to the transmission cooler core so the heat buildup remains as it was before the installation. Indeed, the problems caused may be making the heat problem even worse.

So, here’s what I’d advise you to do. Get the Odyssey back to the service shop and have a sit-down with the tech and the manager or owner. During the sit-down suggest that the shop do the work for free (they should it should be warrantied) and if they don’t want to take responsibility, then point out that since the work was done in their shop that they owe you the implied warranty that comes with every repair. They should honor the warranty especially if you suggest that you might contact a local TV station’s consumer affairs help reporter (it’s amazing just how quickly this suggestion clears up problems).

During the work, I would look over the technician’s shoulder so that everything is installed according to proper directions. I would also ask the factory to step in, as well as a consumer reporter, to assure that the repair meets factory standards. You can contact the factory’s consumer affairs help line to get them in on the problem.

HostgatorMemberFrom the sound of your problem, I think the torque converter has given up the good fight. Some might say the clutches/bands, while others might say the gearing, but I think that your problem is in the torque converter.

The torque converter is the device that sets up a current throughout the tranny, pushing the fluid throughout. The torque converter spins up a set of vanes that spin until the turbine blades on the other side are spinning at the same rate. Once this happens, then, items like the clutches/bands are allowed to spin up so that the engine speed matches the transmission speed so that upshifts can happen.

Of course, the gearing also takes its power from the moving transmission fluid by taking power from the clutches/bands so that you get proper shifting.

At this point in the history of transmissions, it is still some years until the complete computerization of the transmission occurs. With that said, though, there are still some telltales of things to come such as the shift solenoid packs. In 1983, things were still pretty rudimentary but the industry was well into using solenoid packs to assure that the shifts occurred with pinpoint accuracy every time, instead of relying on the somewhat hit-or-miss fashion of the clutches/band packs and gearing.

With all of this said, the biggest hint you gave me of the problem was the fact that the transmission fluid went before you even exited your driveway. With no tranny fluid, you have to motive power in the transmission. Though I don’t doubt you checked the level of the fluid, I would suggest you give it another try to see if there is anything still in the transmission. If not, then you have a serious problem. It could be overpressure caused by deposits of gunk throughout the device that builds up pressure that was only relieved by it blasting out the filler neck and, most likely, the failure of one or more hoses, as well.

It’s highly interesting that all of this should happen at the same time, but it can. So, once you have checked the fluid level, if there is any, look around to see if any hoses have come loose on the transmission or if there is fluid on the engine block near the filler neck. If there is, your transmission has serious issues that can only be repaired with the installation of a rebuilt tranny which should cure your problem. Of course, it will be expensive at $4,000 but if you don’t do it, then you have a very large paperweight gracing your driveway.

-

AuthorPosts

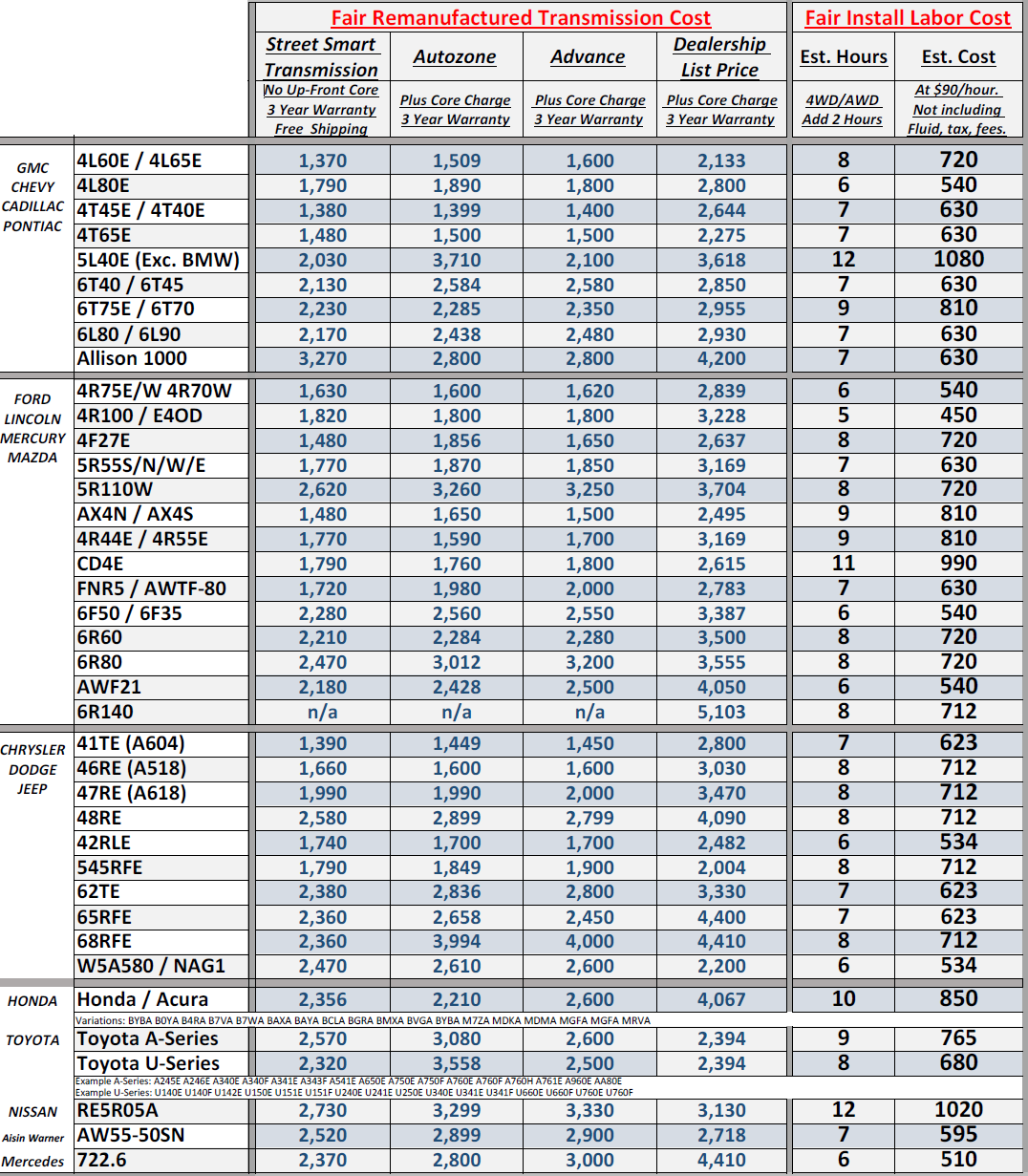

Fair Replacement Transmission Cost by Vehicle

- Use the Year / Make / Model lookup tool to determine what transmission your vehicle has. [transtar]

- Find your transmission model in the table below for fair prices from reputable suppliers. Also fair labor cost for local installation at a local auto repair shop.

- Get a free estimate on a remanufactured transmission by email.

Fair Remanufactured Transmission Price Ranges by Transmission Model Updated May 1, 2018