Torque converter problems are sometimes misinterpreted as symptoms of a failing transmission. Unfortunately, this can lead people to think that they need to spend thousands of dollars to rebuild or replace their automatic transmission when the cost to replace a malfunctioning torque converter is considerably cheaper.

What Transmission Do I Have?

A local auto repair shop will be able to determine whether or not the problem lies in the transmission itself or the torque converter. Finding a reputable shop is very important because as we have mentioned, the symptoms can be very similar and a transmission replacement is considerably more expensive.

In This Guide:

- What Does a Torque Converter Do?

- 6 Signs of Torque Converter Problems

- How to Diagnose the Problem

- Causes of Torque Converter Issues

- Replacement Cost

However, diagnosing the cause of a transmission issue isn’t easy. In many cases, the torque converter will not actually be the source of the problem (you might just have a fluid leak!). The purpose of this guide is to simply help you narrow down the possibilities and educate yourself before you get your transmission checked out.

What Does a Torque Converter Do?

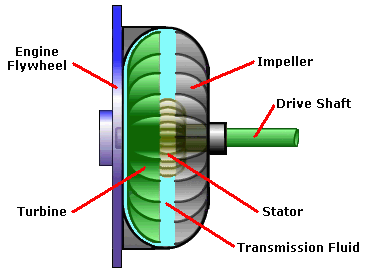

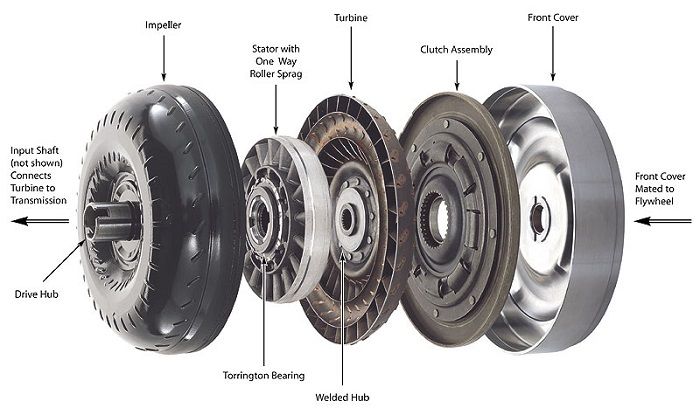

In a nutshell, a torque converter is a fluid coupling that transfers torque from the engine to the transmission. It is mounted between the engine and transmission, bolted directly to a ‘flex plate’ which is spun by the crankshaft.

Internal combustion engines create power by burning fuel that forces the pistons to turn the crankshaft located at the bottom of the engine. This rotational force is transferred to the transmission by the fluid pressure inside the torque converter.

Inside of the torque converter cover lives a series of propeller-like blades called the pump. This assembly spins in unison with the engine crankshaft, forcing transmission fluid onto another blade assembly called the impeller. This second set of blades is connected to the transmission input shaft. The amount of hydraulic pressure that it creates inside the transmission dictates the gear and ultimately, the speed of the vehicle.

The impeller’s speed is regulated by the engine side of this hydrodynamic circuit (ie. speed of the pump blades). When the vehicle is stationary, or the driver applies the brakes, the impeller will slow considerably, while the pump continues to spin. This allows the torque converter to act like the clutch in a manual transmission – it allows the engine to continue running while the vehicle is at a complete stop.

Once the transmission fluid has been hurled onto the impeller blades, it has to return to the pump in order to keep the cycle going. Since the fluid is now flowing in a different direction than the pump, it has to be reversed to avoid slowing down (and stalling) the engine.

To do this, a third finned wheel called the stator is located between the two turbines on the transmission pump shaft. Its blades are precisely angled so that when the transmission fluid hits them, it reverses direction and gets channeled back to the pump. When the vehicle stops, its built-in one-way clutch causes it to stop spinning, breaking the hydrodynamic circuit.

Once the vehicle starts to accelerate from a stop, the stator is once again free to spin. In the split second that the transmission fluid hits the back of the now-released stator, it starts to spin the transmission pump, and briefly multiplies the torque coming from the engine side of the circuit. This causes the transmission pump to force more fluid in the transmission, resulting in movement.

Once the vehicle is in motion, the stator’s one-way clutch allows it to start spinning in the same direction as the other turbines, reversing the fluid flow and completing the hydrodynamic circuit.

After all of the transmission gears have been shifted through and the vehicle has reached cruising speed, the lockup clutch engages, connecting the front cover of the torque converter (aka the pump) to the impeller. This causes all of the turbines to work together in a direct drive/overdrive scenario.

6 Signs of Torque Converter Problems

It isn’t easy to isolate and diagnose a torque converter issue without taking the transmission/drivetrain apart, but there are several symptoms to look for. A few of the signs of a malfunctioning torque converter include: shuddering, contaminated fluid, gears change at high RPMs and strange sounds such as clicking or whirring.

Slipping

Since a torque converter is responsible for translating engine torque into the hydraulic pressure needed to shift gears inside the transmission, a damaged fin or bearing can cause the transmission to delay a shift, or slip out of gear.

Slipping can also be caused by there being not enough or too much fluid in the transmission. You may also experience a loss of acceleration and a noticeable reduction in your car’s fuel economy.

Be sure to check your fluid levels before taking your car to a shop.

Overheating

If the temperature gauge indicates that your car is overheating, it could be a sign that there has been a drop in fluid pressure and there is a problem with your torque converter. If a converter is overheating, it won’t be able to transfer power from the engine to the transmission. This results in poor throttle response, and excessive wear and tear on the internal workings of the transmission.

Low fluid levels or a malfunctioning solenoid can also cause a transmission to overheat.

Shuddering

If the lockup clutch inside the torque converter is starting to malfunction, you may experience shuddering at around 30-45 mph. The sensation is very noticeable and typically feels like you’re driving over a rough road with many small bumps. As the converter switches over to direct drive, a worn lockup clutch can make the transition difficult, resulting in this sensation. The feeling may start and stop abruptly and may not last long, but if you’ve experienced it several times, it’s time to get your transmission checked.

Contaminated Transmission Fluid

A torque converter is filled with automatic transmission fluid (ATF). If the fluid is contaminated, it can do damage the parts inside. This can result in worn bearings on the stator, or damaged fins on one of the turbines.

If you notice a significant amount of black sludge/grime/debris in the fluid it could mean that the converter or transmission itself is damaged. In this case, change the fluid and drive around for a while before checking the fluid again. If the problem persists, get your car checked by a professional.

Higher Stall Speed/Gear Engagement RPM

The ‘stall speed’ is the point at which the engine RPMs are high enough for the torque converter to transfer power from the engine to the transmission. In other words, it is the RPM at which the converter will stop the engine speed from increasing if transmission output is prohibited.

If the torque converter is broken, it won’t be able to transfer the engine’s rotational force into hydraulic pressure correctly. This will result in the transmission taking longer to engage the engine, causing the stall speed to increase. Here is how to do a stall speed test. You’ll have to find out what your vehicles stall speed is beforehand (typically 2000 to 2500 RPM).

Strange/Unusual Sounds

It’s not uncommon for the torque converter to emit strange noises as it begins to fail. Some of the sounds you might hear include a ‘whirring’ sound coming from bad bearings, or ‘clinking’ sound coming from a broken turbine fin.

How to Diagnose the Problem

Here is how you can try diagnose the problem yourself. At each step, listen carefully for unusual slipping, shuddering, lurching forward or strange noises:

- Start your car and let it run for a couple minutes

- Press the gas down lightly several times

- Push the brake and shift the car into drive

- Slowly shift through each gear

- Drive around the block, listening carefully every time you accelerate

Do Not Drive With a Broken Converter

Important to note – a converter can slowly fail over the course of several weeks or even months before it completely breaks down. Driving a vehicle with one that is damaged can be risky as it can completely disintegrate when it breaks down – adding metal debris into the transmission fluid. The contaminated transmission fluid can then make its way into the transmission and cause significant damage or even complete failure, turning what could have been a simple converter replacement into an expensive transmission repair or replacement. To prevent this, pull off the road when it is safe to do so and shut off the engine.

Common Causes of Torque Converter Problems

There are a few reasons why problems can occur. Don’t assume what the problem is until you have your transmission looked at, but here are some general ideas of what it could be.

Bad Torque Converter Needle Bearings

The impeller, turbine and stator use needle bearings in order to turn freely. The bearings separate these rotating components from the converter housing. If these bearings are damaged, you’ll notice reduced power, strange noises and bits of metal in the transmission fluid due to metal on metal contact/grinding.

Damaged Torque Converter Seals

If you notice a transmission fluid leak coming from the bell housing, then you might have a damaged torque converter seal. If your torque converter can’t hold the proper amount of ATF, then it won’t be able to transfer power from the engine to the transmission effectively. This will result in overheating, shifting problems, strange noises, higher stall speeds, and slipping between the gears. The bad seal will need to be found and replaced.

Worn Torque Converter Clutch

Automatic transmissions have a number of clutches located throughout the assembly. A torque converter clutch is responsible for locking the engine and transmission into direct drive.

If the torque converter has been burned by overheating, become jammed/locked up due to distortion or contaminants in the transmission fluid have damaged the friction material on it, then your car may stay in gear even though you come to a stop. The converter can also shake and not lock itself into direct drive if the friction material on the clutch plate has worn away.

Faulty Torque Converter Clutch Solenoid

A torque converter clutch solenoid regulates the amount of transmission fluid that the converter’s lockup clutch receives. If this electronic device can’t accurately meter the fluid pressure, then the lockup clutch will not work properly as a result of too much or too little fluid supply. This can result in loss of the direct drive function, poor gas mileage and engine stalling.

Torque Converter Replacement Cost

If you’ve noticed one or more of the above symptoms, then it’s possible that your torque converter is malfunctioning. The cost of getting it repaired can be higher than simply replacing it, so be sure to have a mechanic/technician take a look.

| Repair | Cost Range |

|---|---|

| DIY | $150 to $500 |

| Transmission Shop | $600 to $1000 |

If you plan to do the work yourself, then you’ll be looking at a repair cost between $150 and $500.

Repair shops will charge between $600 and $1000 to replace a torque converter.

The torque converter itself is relatively inexpensive (between $150 and $350, depending on the vehicle), but 5-10 hours of labor is involved since the transmission must be removed in order to replace the torque converter.

The fluid should also be flushed/changed at the same time, which may or may not be included in the price a shop gives you.

What Transmission Do I Have?

Over to You

What problem do you think your torque converter has? What symptoms is your car experiencing?

I have a 2010 chevy impala it’s supposed to have a an automatic transmission but every time I come to any stop I have to basically drive it like a manual transmission. And start in 1st gear, then switch each gear accordingly. Cuz when I am in drive it doesn’t get in to the right gear or any gear or won’t engage.

The car wont shift to Drive or Reverse. Its an automatic transmission Ford Everest 3.2L AWD

It is really a strarting problem with my daughters 2013 accord v-6 automatic. She has had 3 starters replaced and each time the issue returns which is the starter is not engaging the flywheel which according to the Honda dealer is permanitly attached (welded) to the torque converter. Sometimes you have to push the starter button several times and then it will work, other times it is fine. The dealer service rep told me the torque converter moves a few thousands of an inch back and then disengage from the starter and sometimes rocking the car will allow it to move back where it belongs.Of course they actually wanted $3600. to replace the torque converter and when I said no they dropped to $3000. Of course I would never pay anything close to that.

My work van slips in all drive gears except reverse reverse works fine. All drive years slip if given any kind of gas and slip in and out on the highway. It makes a loud sound in D1 &D2 it’s not a thump or squeal or even a whine more like a steel cylinder slid across concrete if you’ve ever heard that sound. It does make a squeal at start up that comes from the bell housing. I’ve looked at the flex plate and there’s no cracks the torque converter doesn’t leak. It does look like it leaked A LITTLE from the rear of the transmission at some point. I haven’t had it long,less than8 months. Like I said reverse works fine it’s the drive gears that are the problem. Any help would be greatly appreciated because of the squeal from the bell housing I thought maybe the torque converter is bad but why would reverse work fine? Thank you Kelly Dunnigan

Rebuilt engine nothing was wrong with transmission before that , reinstall engine and transmission replaced fuild but now the transmission wont engage .when I go through the gears nothing happen there is no power to the wheels and going back to park there is a grinding noise. I replace the solenoids and still no drive

Please help.

2008 Jeep wrangler. First trans died @260K miles by disengaging under acceleration on an off ramp, Able to manually shift into first gear and limp home. Replaced by dealer. internally grenaded. 2nd (dealer installed) lasted ~1200 miles. Several jolts while stopped, then slipped into neutral with no recovery. Dealer lists disintegrated clutch pack as finding and replaced under warrenty. 3rd transmission failed this morning Same general symptoms. Unknown if dealer has been using same torque converter through out

My torque converter needs to be replaced for my Toyota Camry 2012

Lurches into gear..a pause before engaging into gear..then stops abruptly when shifting into 2nd

Im having same problem 2013 treverse

The car will barely back up when shifted to “R”, The engine just races, but the car doesn’t move. After a couple of minutes of applying the throttle, the car will start to move in reverse, but hesitantly. When I put the car in drive, it accelerates normally and shifts through all three gears normally.

This is a 1989 GM THM400 or a 3L80, depending on what nomenclature you use.for the turbo hydromatic 3 speed made by GM..It seems like a torque convertor issue but I’m not sure. The fluid level is fine and the fluid does not look dirty or smell burnt.

Transmission leaks after being shut down, also pukes oil out the filler tube

After the truck is driven for a bit and warms up the Tc wont unlock when I hit the break or come to a stop and wants to kill the engine. I can slightly rev the engine and it will make the Tc unlock. And sometimes after the transmission is warmed up and the TV starts acting up occasionally it doesn’t want to shift into 2and if I’m pressing on the gas but if I let off of the accelerator it will shift fine and 2and is the only gear it’s done this in.

I was driving and it made a revving sound and it would not go forward even when pressing on the gas. When you put it in any gear it will not go forward or reverse.

Runs good in park put it in gear shuts off

2017 jeep wrangler with W5A580 auto transmission. Just started making a grinding noise when running in park When you shift into any gear it has a loud squealing-whining sound until you accelerate. shifts fine and no noises at a steady 45-70 mph but slow down and squealing begins.

The car will barely drives, like transmission slips. OBD Code reads torgue converter

It’s leaking fluid and the fly wheel looks

warped and making a clanking noise and it won’t shift in second be when I put it in park it stays in gear and

4t65E non HD..out of 2000 regal LS

Wont go into any gear.

Thinking the torque Converter.

Was also shuddering

The truck is a 2005 Nissan Titan King cab 2wd with the 5.6 v8 339 engine. When you accelerate from a stopped position in drive gear the truck shudders and feels as if its resisting the c9mmand by the gas pedal to move the vehicle forward. Once youre moving it smoothes out. Then once you drive about 1 block at a normal acceleration rate it shifts fine until youve driven about that 1 block distance and then it begins to rev out while pressing the gas with no forward propulsion. Pullover stop engage park shut off the engine. Wait a few seconds start it back up and put it in drive it engages. Couple hundred feet down the road it begins to slip again and instantly begins revving out if you oress the gas. Also if you accelerate fast it hesitates to switch gears revbing upto high rpms only to switch gears when you oet off the gas pedal but still after about a block you lose acceleration. My limited knowledge tells me the torque converter is bad or at least i hope… Just bought the truck. It ran fine yesterday when i bought it now today after a half a day driving around town here and there to run errands. This issue has happened.

So car runs fine at cold temperature. If I drive say a distance of 100km then come to a stop or slow down I start to hear a ticking noise in the engine bay and then the car stalls. I turn off the key and turn the car back on and I’m fine again. It only happens when I come to a stop and only at operating temperature. I’m thinking it has to be something with the torque converter. Also at cold when I drive at 90km/her the car vibrates as if my wheels are out of balance. Has to be the torque converter clutch solenoid. Any suggestions or tests I can do to confirm this? Car is a 2018 Elantra with automatic transmission. Only started happening within the last 3 months. Also sometimes at a drive thru I leave car in gear and apply park brake. Could this contribute to the issue? Thanks

I put truck in drive n it won’t move but I step on the gas n jumps forward n I take my foot off the gas n it won’t in till step on it ?

My torque converter appears to be locking and unlocking once it warms up at lower speeds when I accelerate usually on a hill or when I am trying to get after it, pass someone or just put my foot into it, it seems to do it right before it shifts, the tranny was rebuilt not more than a year and a half probably 15 months, not sure if he replaced the torque converter, but I know he installed a performance shift kit that has a hard shift to it. And I wondered about my dipstick becuz while checking after rebuild it read as if way too much fluid altho the guy who rebuilt said it took 6 qrts. In the pan but becuz problems I drained pan completely aprx 2 gals and it was dirty fluid not burnt but not totally red either but no metal at all and when I filled up back according to dipstick while running it only took 1 gal, or 4 arts. But that read it on the dipstick right in between the 2 dots. It rides perfect when it cold and after I get past 40-45 but it also doesn’t always do it. It feels like no or considerably less acceleration kinda bucking sensation. I first thouht it was my engine. Is this my torque converter probably I have had zero codes no check engine light..